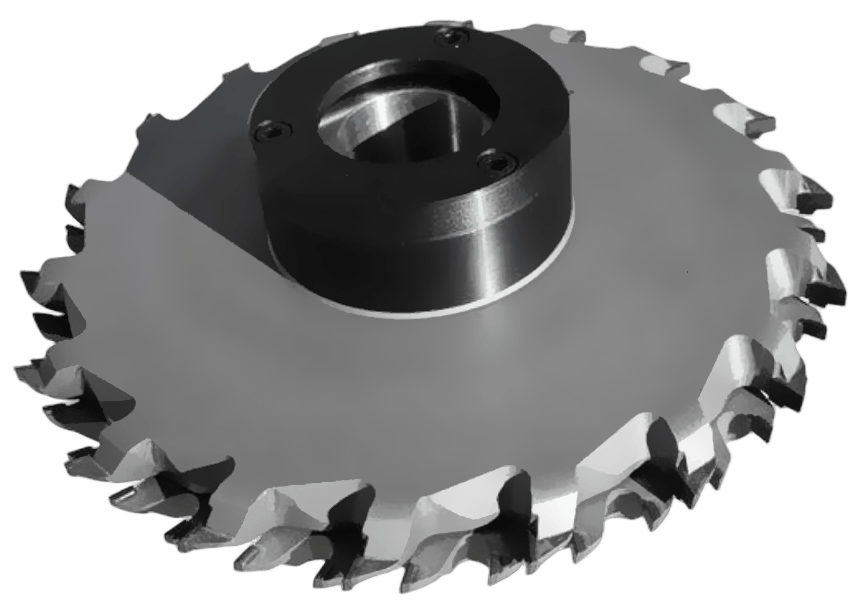

With the wood-based panel processing industry, especially the development of the laminate wood processing industry and the trend of CNC woodworking machinery, traditional woodworking tools have been gradually eliminated, which promotes the rapid development of diamond woodworking tools,because the diamond PCD tools have the following characteristics.

(1) It owns the sharpness of the cutting edge. The main parameter of cutting tool sharpness is the blunt radius of cutting edge p. In the case of a certain back Angle of the tool, the smaller the blunt radius of the cutting edge, the smaller the deformation of the wood below the cutting plane, and the better the surface quality of the work-piece. From a physical point of view, there is a limit to the blunt radius p of the sharpest edge of a material. By calculation, the minimum blunt radius of the diamond cutting edge can reach 2nm. However, the blunt radius of the edge of the diamond tool after precision grinding can be about 0.5μm, while the blunt radius of the ordinary tool is 5~30μm.

(2) It owns chemical stability. The diamond tool has good chemical stability. Due to its high thermal conductivity, specific heat capacity, and low coefficient of friction, the temperature rise of the friction surface is only 20% of that of other tool materials. Moreover, diamond has a low coefficient of linear expansion and small thermal stress, so it also has good thermal stability and extremely high hardness at high temperatures.

(3) It owns wear resistance. Even if the diamond pcd tool's size, Angle, and cutting parameters are the same, its durability also varies greatly due to the microstructure of the tool's cutting edge. For example, when cutting laminate wood flooring with a quantitative of 45g/m2 wear-resistant paper, the diamond finishing knife with good performance can process about 2000m2 per cutting point, and some diamond finishing knives can only process hundreds of square meters. In addition to the cutting and Angle parameters, the diamond crystal orientation and the roughness of the front and back of the tool are also factors that affect the durability of the diamond pcd tool. The roughness of the cutting edge of the tool depends on the roughness of the front and back of the tool's face. The roughness of the grinding cutting edge can reach Ry10nm, and its wear resistance is fully reflected.

The loss forms of diamond cutting tools are different, but there are two basic loss forms: the sudden collapse caused by the accumulation of small brittle damage; the smooth wear surface formed by little wear (normal wear). Under normal wear conditions, the PCD milling cutter can process wood for about 25000h, while the carbide milling cutter can only maintain about 75h. When milling a high-density fiberboard, PCD forming milling cutter can maintain a cutting length of about 1 million m. A carbide milling cutter can only mill 0.5 million to 1.0 million m. According to the test data, the durability of the diamond tool is 80 to 360 times that of the cemented carbide tool under the same conditions. Because diamond (PCD) woodworking tools have the advantages of high hardness, high wear resistance, high thermal conductivity, long life, high processing efficiency, and greatly reduced total cost, in recent years, diamond woodworking tools have gradually become the leading tool in wood processing.

Contact: Nina Qiao

Phone: 8613526572721

E-mail: cutting@zy-superhardtools.com

Whatsapp:8613526572721

Add: AUX Industry,Zhengzhou City,Henan Province,China

We chat