PCD turning and grooving tools are most suitable for high precision and low roughness turning of non-ferrous metals such as copper, aluminum, and its alloys.

PCD Turning and Grooving Tools are most suitable for high precision and low roughness turning of non-ferrous metals such as copper, aluminum, and its alloys. It also can be used for gold, silver, and other rare precious metal turning processing. The machining accuracy of the workpiece can be controlled at about 1 micron by pcd turning and grooving tools, and the surface roughness can reach 0.025 microns.

(1) Lower cost and grinding cost

(2) High impact resistance, heavy cutting and intermittent cutting

(3) High hardness, good wear resistance, long life, reduce the number of tool replacement, can be a long time and high precision processing products

(4) Low friction coefficient, reduce the generation of chip

(5) Excellent finish to machining surface, rough processing and fine processing can be done at the same time

(1) Non-ferrous materials: silicon aluminum alloy and aluminum, Babbitt alloy, bronze, brass alloy and copper, sintered hard alloy, titanium alloy

(2)Bakelite, carbon phenolic resin, wood, ceramics, glass, glass filled polypropylene.

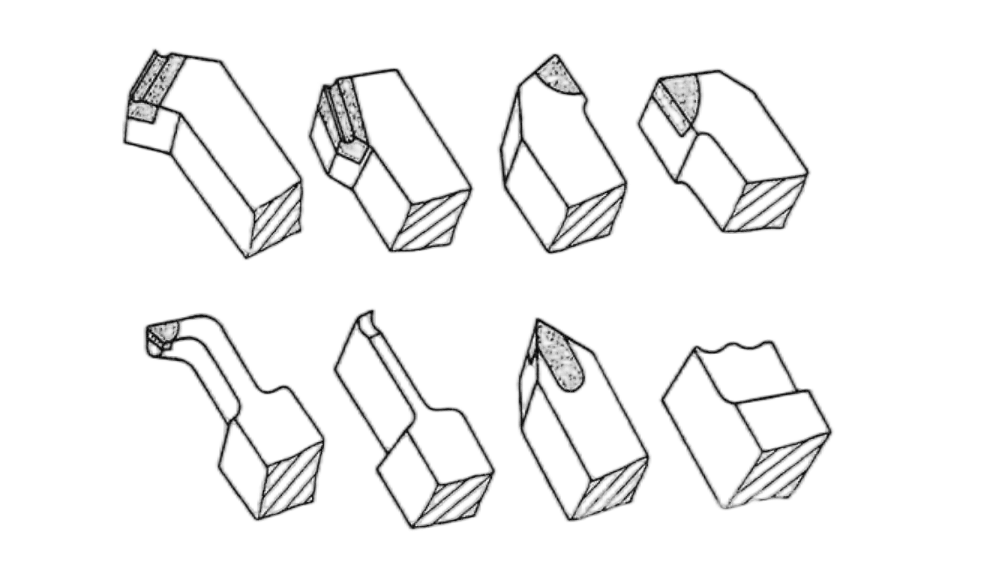

Specification:variety of PCD Turning and Grooving tools,we accept non-standard customization as the drwing offered.

Contact: Nina Qiao

Phone: 86-13526572721

E-mail: cutting@zy-superhardtools.com

Whatsapp:86-13526572721

Add: AUX Industry,Zhengzhou City,Henan Province,China

We chat