The pcd diamond turning tool is a vital machining tool used in precision turning. It is most suitable for high precision and low roughness turning of non-ferrous metals such as copper, aluminum, and alloys. It can apply to turning rare precious metals such as gold and silver. The machining accuracy can reach 1 micron, and the surface roughness can reach 0.025 microns,

The pcd diamond turning tool is a vital machining tool used in precision turning. It is most suitable for high precision and low roughness turning of non-ferrous metals such as copper, aluminum, and alloys. It can apply to turning rare precious metals such as gold and silver. The machining accuracy can reach 1 micron, and the surface roughness can reach 0.025 microns,

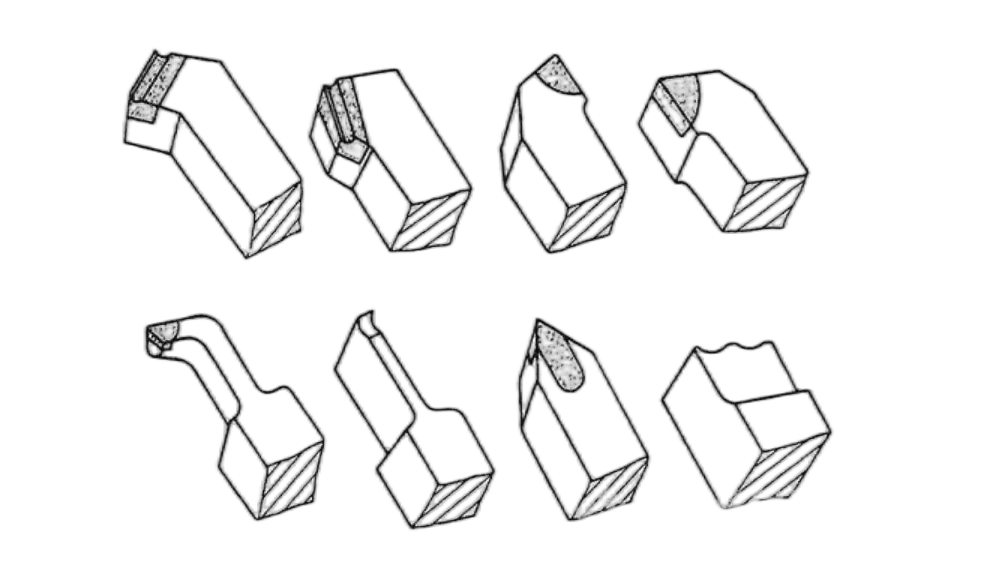

Special grinding processing, according to the requirements, forms the geometric parameters. The precision is very high. Many aspects need to be paid attention to in use:

1. Diamond cutters generally turn workpieces on precision lathes, and they are also suitable for ordinary lathes with good general accuracy and slight vibration. Still, the speed of vibration must be low and smooth.

2. When installing the tool, the tooltip must be as high as the center of rotation of the steel parts, and the polishing edge must be parallel to the going direction. We will inspect and test cutting with a magnifying glass five times after adjusting the well next cutting.

3. Diamond turning tool is a precision cutting tool that is not allowed to wear significantly. Increasing the cutting edge's radius will affect the workpiece's surface quality after cutting, so observe the cutting process. When the blade is sharp, the chip is complete, the phenotype is small, and the workpiece surface is smooth. If the edge gets dull, the chip deformation is significant, and there is an extrusion tearing phenomenon and a noticeable burr on the workpiece at the cutting source.

4. After the workpiece rotates, the tooltip can contact the surface of the workpiece; Before the tooltip leaves the workpiece, it must not stop first so as not to damage the tooltip. We can place a dial gauge on the middle drag plate to control the cutting depth effectively.

5, the cutting speed is generally 80-150m /min, such as machine tools to meet the precision cutting requirements, but also can choose a higher cutting speed. When the cutting depth is 0.01-0.2mm, and the workpiece surface roughness is less than Ra 0.05 micron, ap<0.01mm, the feed is generally (0.02 -- 0.04)mm/r. During cutting, we need sufficiently cool workpieces and tools to remove chips.

6. In general, the power and rigidity of the machine tool and the ability to form iron chips often restrict factors in the rough turning process. If we select the best cutting parameters, that will significantly increase the maximum metal removal rate. We also need to consider the combination of low cutting speed and the adequate power of the machine tool. Sometimes when the power of the machine tool is too low, it will lead to the use of the diamond turning tool. It requires us to reduce the cutting speed to a certain extent to get the right power when we choose the feed and speed.

Contact: Nina Qiao

Phone: 86-13526572721

E-mail: cutting@zy-superhardtools.com

Whatsapp:86-13526572721

Add: AUX Industry,Zhengzhou City,Henan Province,China

We chat