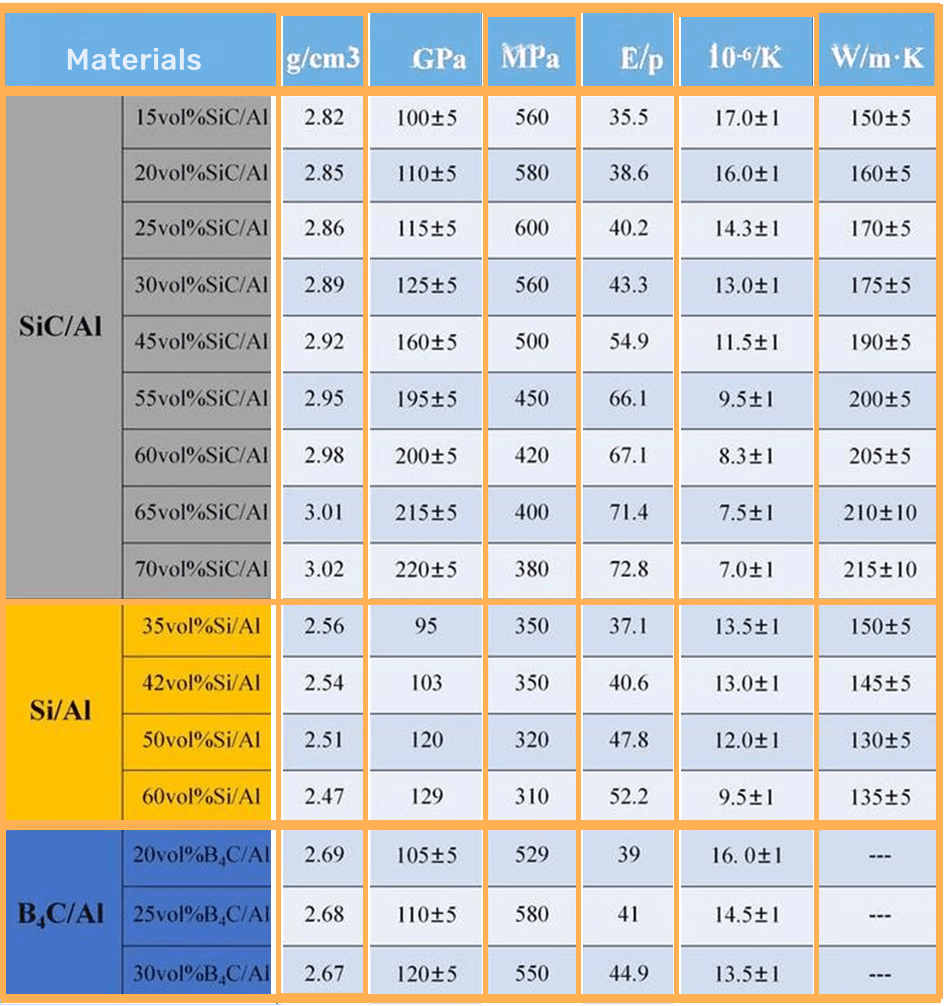

Aluminum-based silicon carbide, referred to as Al Sic (some literature is written as SICP/Al or Al/Sic, Sic/Al), is a kind of particle-reinforced metal matrix composite material composed of silicon carbide (Sic) and granular aluminum, is the combination of high thermal conductivity of metal and low thermal expansion of ceramics, the density is 1/3 of steel. It can meet multi-functional characteristics and design requirements. Its strength is higher than pure aluminum and medium carbon steel, with high thermal conductivity, wear resistance, expansion, stiffness, density, cost, and other comprehensive excellent performance. The following figure shows the microscopic interface of aluminum-based silicon carbide

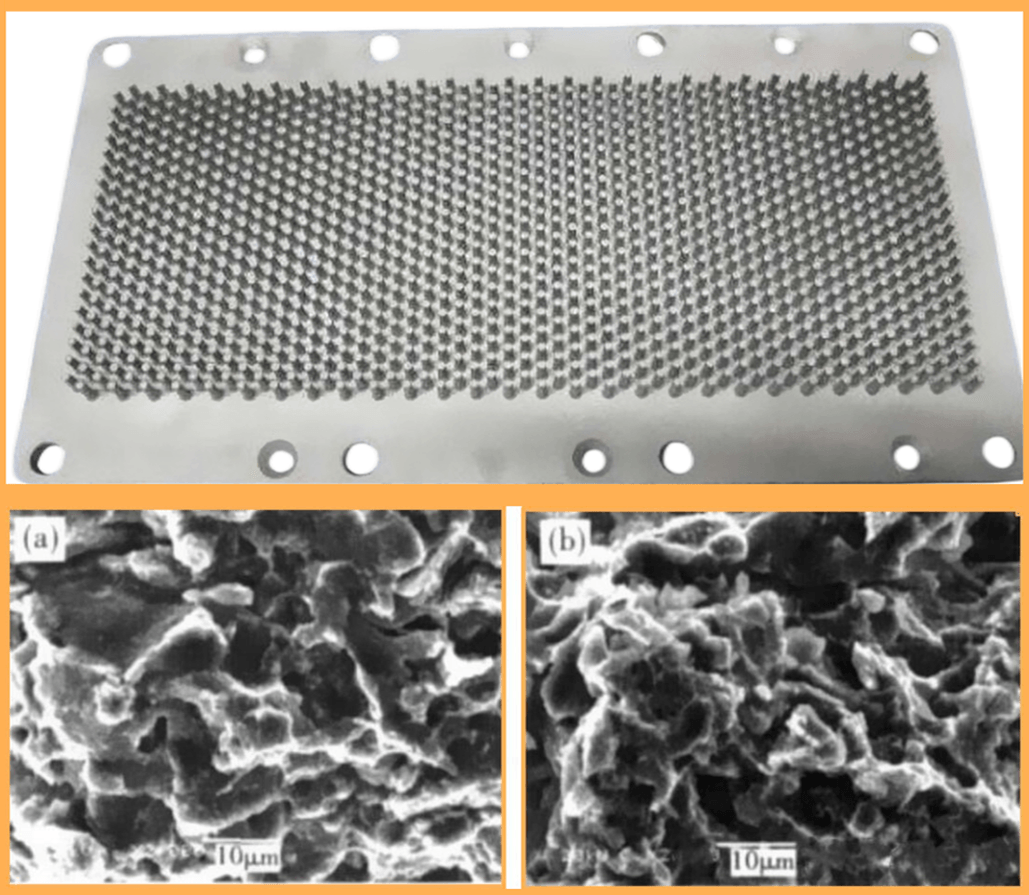

With excellent hardness, toughness, high plasticity, high modulus, and other advantages, it is widely used in aviation, aerospace, electronic chips, high-speed rail, satellite, and other fields.

The silicon carbide particle reinforced aluminum matrix composite material prepared by powder metallurgy method is used in the fighter fin; instead of the original 2214 aluminum alloy skin, the stiffness is increased by 50% so that the life is increased from the original hundreds of hours to the designed life of 8000h, the life is increased by 17 times.

The die forgings (hub splints and sleeves) for connecting helicopter rotor systems made of this material have been successfully used in new helicopters. The application results are as follows: compared with aluminum alloy, the component's stiffness is increased by about 30%, and the life is increased by about 5%; Compared with titanium alloy, the weight of the component is reduced by about 25%.

The material replaces copper-covered molybdenum and copper-covered invar as the printed circuit board core, which can reduce the weight by 70%. Since the thermal conductivity of this material can be as high as 180W (m·K), the operating temperature of the electronic module is reduced, reducing the need for cooling.

Instead of beryllium material for inertia and known as the "third generation aerospace inertial device material." It has been officially used in a certain type of inertial ring laser gyro guidance system in the United States, and has formed the national military standard of the United States (MILM 46196). In addition, alternative beryllium materials have been successfully used for the Trident missile's inertial guidance ball and its inertial measurement Unit (IMU) inspection port cover, and achieved a cost of two-thirds lower than beryllium materials.

Aluminum-silicon carbide IGBT substrate is an essential part of high-speed rail. Aluminum-based silicon carbide is an ideal material for power electronic substrate and substrate, which can achieve good working match with electronic chips after welding.

As a modern new composite material, aluminum-based silicon carbide composite material has many advantages. Still, it also has obvious disadvantages: the mechanical processing is difficult, the tool wear is fast, the production cost is high, and the efficiency is low. The main reason for the difficulty in processing is that the hardness of silicon carbide-reinforced particles in aluminum-based silicon carbide composite materials is very high; another name for silicon carbide is emery, the hardness is second only to diamond, while the surface of aluminum-based silicon carbide composite materials is rough, the distribution of silicon carbide hard points is not uniform, the tool wear is faster in the cutting process. The cutting can produce large vibrations, affecting the processing accuracy. Therefore, the choice of tool and machine tool in the processing is particularly important.

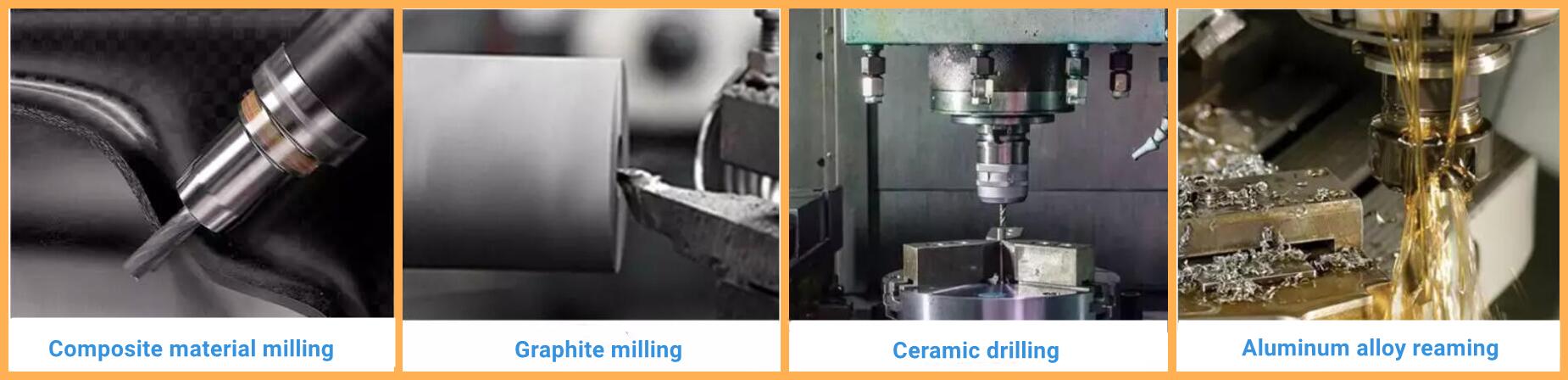

(1) Traditional machining (turning, milling, drilling, and others): alloy tools, PCD diamond tools

(2) Milling processing: diamond grinding wheel

(3) Laser processing: drilling, cutting, marking

(4) Ultrasonic processing

The mach-inability becomes worse with the increase of the sic particle volume fraction. Using special processing technology to process high-volume aluminum matrix composites with silicon carbide particles can not be compared with conventional machining methods, such as turning milling, regarding removal rate, surface quality, and processing efficiency. Therefore, conventional mechanical processing is still the main method for aluminum matrix composites.

Aluminum-based silicon carbide composite materials' common processing methods are milling, drilling, etc. surface, hole, and groove processing; to better control the cost, rough processing can be processed by carbide cutting tools, finishing with PCD cutting tools milling and drilling, carbide tool hardness is lower than aluminum-based silicon carbide, low durability, but can be large margin cutting, PCD tool hardness is high, but the cutting margin is small, suitable for finishing. It can ensure the dimensional accuracy and surface roughness of aluminum-based silicon carbide composite parts.

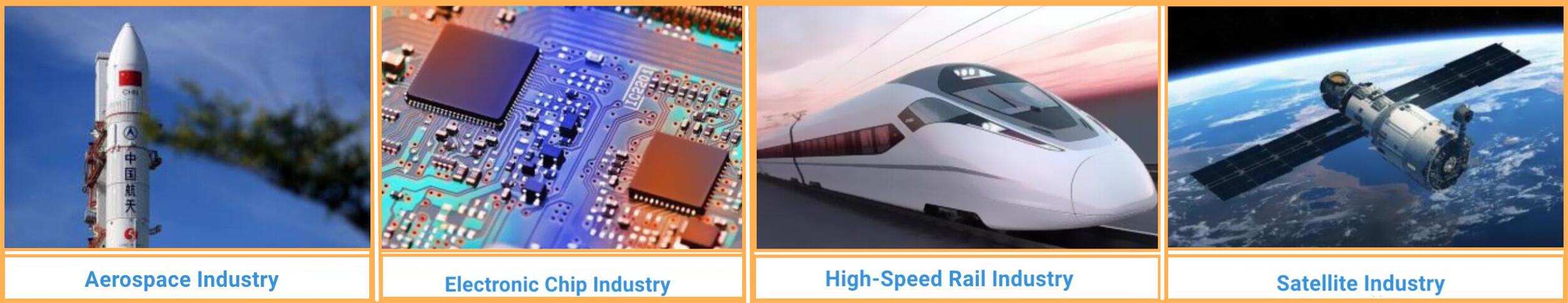

For aluminum-based silicon carbide composite materials, the commonly used knife has a PCD milling cutter and PCD drill, and the common PCD tool particle size is 010,025,302, according to the composition of aluminum-based silicon carbide to choose different materials for efficient processing. Figure 1 is a PCD milling cutter for processing aluminum-based silicon carbide composites. Figure 2 shows the PCD drill bit.

Figure 1

Figure 2

The following are the case parameters of ZY-superhard PCD milling cutter milling aluminum-based silicon carbide

Cutting tool: φ4 PCD end mill

Machine tool: Beijing Jing Machine

Processing part: step cleaning root

Application industry: Satellite parts

Use effect: ZY super hard PCD cutter, a single cutting edge service life of 4 hours, is 12 times the life of cemented carbide cutter, is a domestic brand of PCD cutter life of 1.5 times.

Because of the brittleness and hardness of aluminum-based silicon carbide material, the choice of tool material is a decisive factor in the life of the tool itself, machining efficiency, production cost, and work piece processing quality. Tool cutting withstand the impact of high temperature, high pressure, mechanical wear, and impact, so in the process of processing aluminum-based silicon carbide, the tool should have the following characteristics to be suitable for processing aluminum-based silicon carbide materials:

usually, the hardness of the cutting tool material is higher than the hardness of the work piece material; the harder the tool material, the better the wear resistance. Currently, the PCD tool is the highest hardness tool for processing non-metallic materials, such as 010 material hardness 8000HV; processing 2700HV volume fraction of 50% aluminum-based silicon carbide is no problem.

In the processing process, the tool must have good strength and toughness to withstand the cutting force and impact load. The compressive strength of the PCD tool is better than that of high-speed steel, carbide, and other tools.

Tool materials should have high heat resistance, withstand high cutting temperatures, and not oxidize at high temperatures. The thermal conductivity of the 025 material PCD tool is 700W/mk, which is 1.5-9 times that of cemented carbide, even higher than PCBN and copper. At the same time, the coefficient of thermal expansion is only 0.9×10-6~1.18×10-6, which is only equivalent to 1/5 of cemented carbide.

the tool material should have better processing performance and higher cost performance; the PCD tool belongs to artificial diamond, is low cost, has a good economy, and can be made into different structures of the tool, such as 302 material PCD milling cutter, PCD drill, PCD reamers, PCD turning tool, PCD slot (grooving) cutting tool.

PCD tool as an artificial diamond, the hardest cutting tool, compared with carbide tools; PCD tool has a longer life to ensure higher surface quality and dimensional accuracy of aluminum-based silicon carbide parts. At the same time, 010 material, 025,032 material, and other PCD tools in the process of processing aluminum-based silicon carbide parts should also consider the factors of the machine tool to choose the machine tool with better rigidity better to meet the processing requirements of aluminum-based silicon carbide.

Contact: Nina Qiao

Phone: 86-13526572721

E-mail: cutting@zy-superhardtools.com

Whatsapp:86-13526572721

Add: AUX Industry,Zhengzhou City,Henan Province,China

We chat