Have you ever wondered what's behind the roaring performance of your vehicle's engine? You might be surprised that Polycrystalline Diamond (PCD) tools are crucial in engine manufacturing, enhancing efficiency, reducing costs, and contributing to your vehicle's longevity.

If you are unfamiliar with PCD tools, imagine a super-hard, long-lasting tool capable of enduring the intense conditions of machining applications, especially in the engine industry. Now, what makes these tools so extraordinary?

PCD tools comprise tiny diamond particles bonded together under high-pressure and high-temperature conditions. The resulting material is a highly durable tool perfect for extreme machining scenarios, making them invaluable in engine manufacturing.

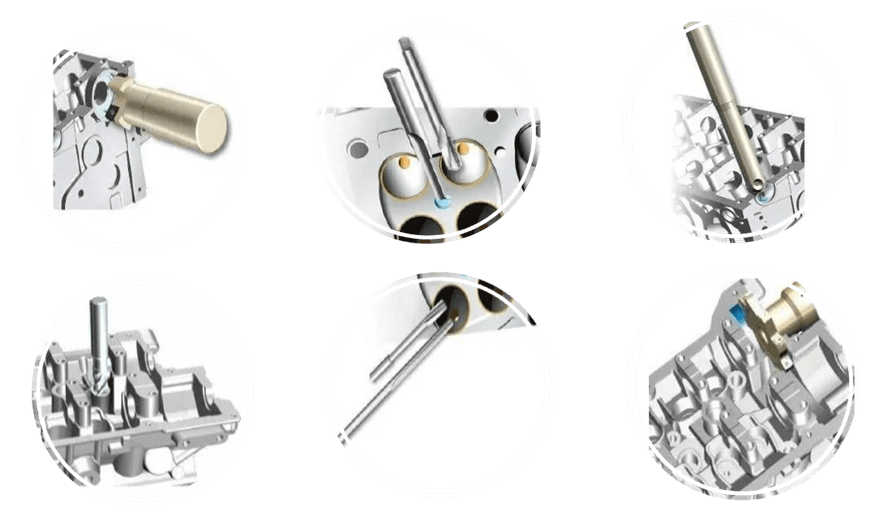

There's a wide variety of PCD tools at the disposal of engine manufacturers, ranging from drills and reamers to end mills and inserts. The diversity ensures these tools cater to the engine industry's vast machining needs.

So why are PCD tools such a big deal in the engine industry? Let's explore.

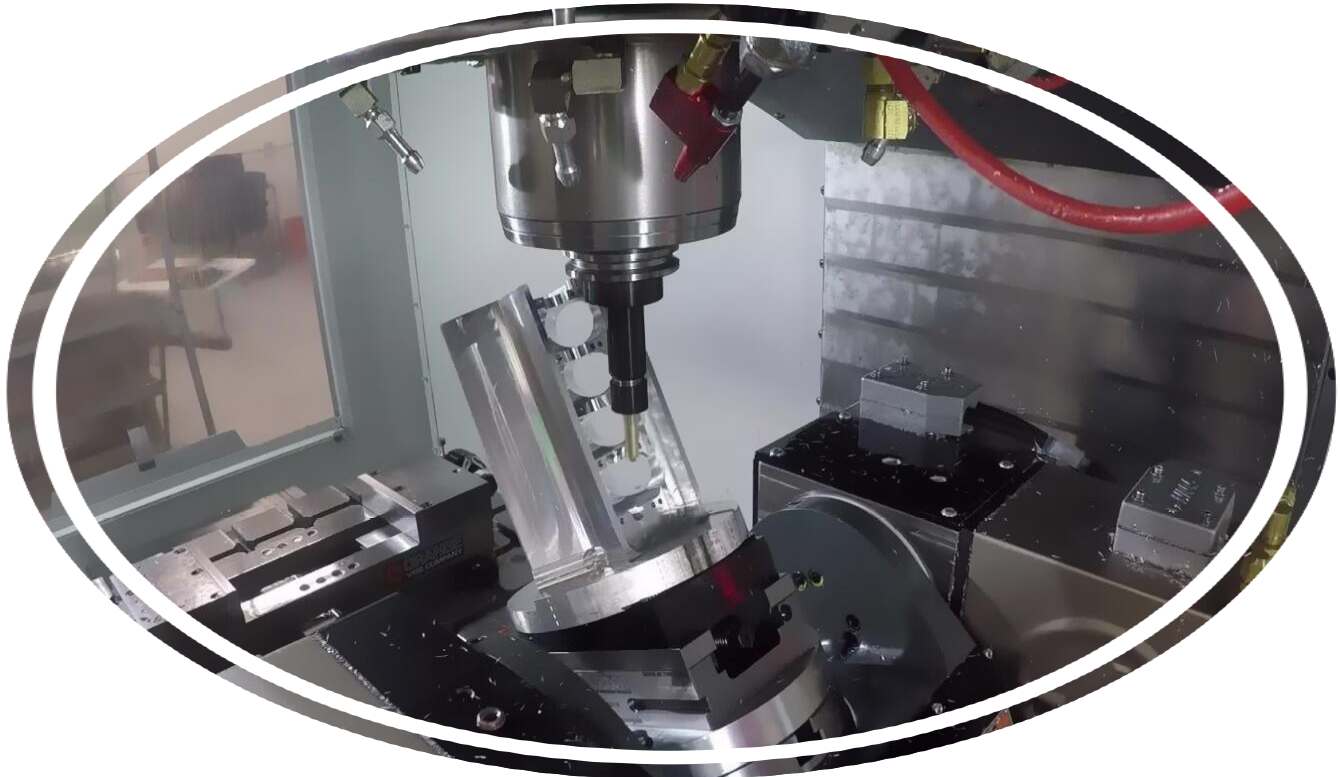

PCD tools excel in providing efficient machining processes due to their high wear resistance. That means more engine components can be produced simultaneously, boosting overall performance.

Thanks to their longevity, PCD tools require fewer replacements. This reduction in downtime for tool changes and the associated costs saves engine manufacturers considerable resources.

Because of their superior cutting edges, PCD tools produce components with smoother surfaces and more precise dimensions, contributing to the durability and performance of engines.

Let's dive deeper into how PCD tools are applied within the engine industry.

PCD tools are essential in the machining of cylinder heads. With their high-precision capabilities, they ensure the accurate creation of intricate geometries.

PCD tools offer superior performance in engine block machining, enabling the efficient production of high-quality engine blocks.

For the precise machining of fuel injection system components, engine manufacturers rely on PCD tools. They guarantee the high accuracy required for these critical engine parts.

The relationship between PCD tools and the engine industry isn't ending anytime soon. Let's gaze into the future.

Continual advancements in PCD technology are creating more effective and diverse tools, further enhancing their application within the engine industry.

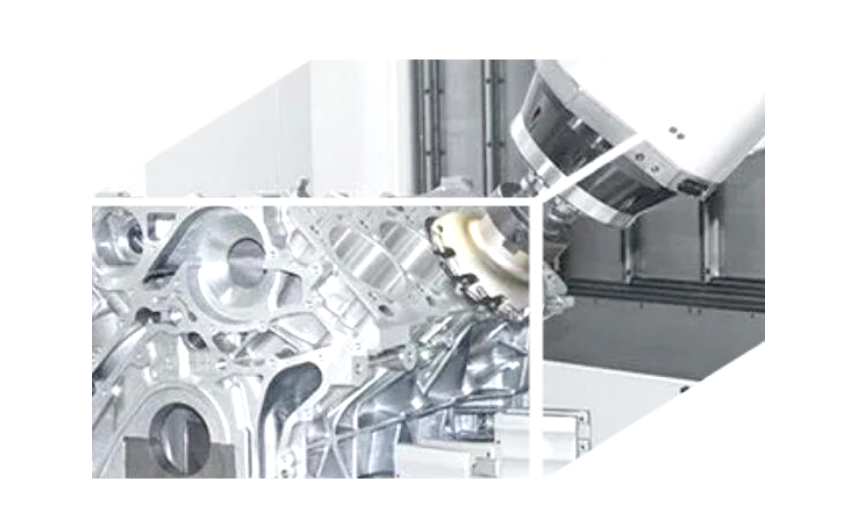

As the engine industry embraces Industry 4.0, the usage of PCD tools is bound to evolve.

The integration of AI and robotics is set to redefine how PCD tools are utilized, potentially leading to unprecedented efficiency and precision.

In conclusion, PCD tools are the unsung heroes of the engine industry. Their extraordinary properties and versatility make them indispensable in manufacturing high-performance, durable engines. As technology evolves, so will the role and capabilities of PCD tools, securing their place in the engine industry's future.

What does PCD stand for? Polycrystalline Diamond.

What are the benefits of using PCD tools in the engine industry? PCD tools enhance efficiency, reduce operational costs, and increase the longevity of engine components.

What types of PCD tools are commonly used in the engine industry? Drills, reamers, end mills, and inserts are common PCD tools.

How does the future look for PCD tools in the engine industry? With advancements in PCD technology and the impact of Industry 4.0,the future looks promising for PCD tools in the engine industry.

How do PCD tools contribute to the durability of engines? PCD tools produce components with smoother surfaces and more precise dimensions, enhancing engines' durability and performance.

Contact: Nina Qiao

Phone: 86-13526572721

E-mail: cutting@zy-superhardtools.com

Whatsapp:86-13526572721

Add: AUX Industry,Zhengzhou City,Henan Province,China

We chat