It is a kind of polycrystalline tool material, and it is made by laying a layer of cubic boron nitride (CBN) single crystal fine powder (0.5~1.6mm thick), adding a binder, and pressing under high temperature (1400~2600℃) and high pressure (7~9Gpa).

Because of the small particle size of single-crystal CBN and the cleavage plane of single-crystal CBN, we can not directly use it in machining. Therefore, most industrial cutting tools are polycrystalline cubic boron nitride (PCBN).

PCBN (Cubic Boron Nitride) dose not react chemically with iron and is ideal for tools machining hard ferrous metal space (HRC 45~80)such as high-speed steel, bearing steel, cast iron, etc. PCBN is typically used to machine brake discs, engine blocks, engine cylinder liners, brake drums, flywheels, valve seats/guides, gears, mold and die parts, etc.

I. Characteristics of polycrystalline cubic boron nitride

1-1. High hardness and excellent wear resistance

CBN is a synthetic product, its hardness is second only to diamond, and the grain hardness can reach HV8000~ HV9000, much higher than ceramic and hard alloy. The hardness of the PCBN composite sheet (usually HV3000 ~HV5000) mainly depends on the content of CBN; the general scope of CBN is between 40% and 95%. With the increase of CBN content, the hardness of PCBN increases. There is no monotone relationship between wear resistance and CBN content. There are different optimum values under other processing conditions. When the content of CBN is about 55%, the tool is the most wear-resistant.

1-2. High thermal stability

The heat-resistant temperature of cubic boron nitride is as high as 1400 ~1500℃, almost twice as high as diamond's (700-800℃). Cubic boron nitride in 1370℃ above the cubic crystal into a hexagonal crystal and began to soften, using it to make a tool can be high speed cutting superalloy; its cutting speed is 3 to 5 times higher than carbide tool.

1-3. Strong chemical stability

Cubic boron nitride is an extensive chemically inert material; acid and base are stable in the neutral reducing gas medium. Carbon at 2000℃ reaction and iron group materials at 1200~ 1300℃ reaction is not. Cubic boron nitride has much less bonding and diffusion with various materials than carbide and can be used to cut iron and steel materials that diamonds cannot miss.

1-4. Excellent thermal conductivity

The thermal conductivity of cubic boron nitride is 79.54w/m.k, second only to diamond (146.5w/m.k). And with the temperature increase, the thermal conductivity of cubic boron nitride increases gradually, which is beneficial to the temperature control in the cutting zone and the tool to reduce the diffusion wear.

1-5. Lower friction coefficient

The friction coefficient between PCBN and different materials is 0.1~0.3. The lower friction coefficient reduces the cutting force and cutting temperature, and it is not easy to produce chips, which is conducive to improving the surface quality of processed materials.

1-6 Can be re-grinding

The polycrystalline cutting-edge PCBN tool adopts advanced Mosaic technology and is firmly embedded. We can take 180-240 mesh resin or vitrified bond diamond grinding wheels to grind the devices, which is convenient for users and reduces the tool cost.

2. Classification of polycrystalline cubic boron nitride cutting tools

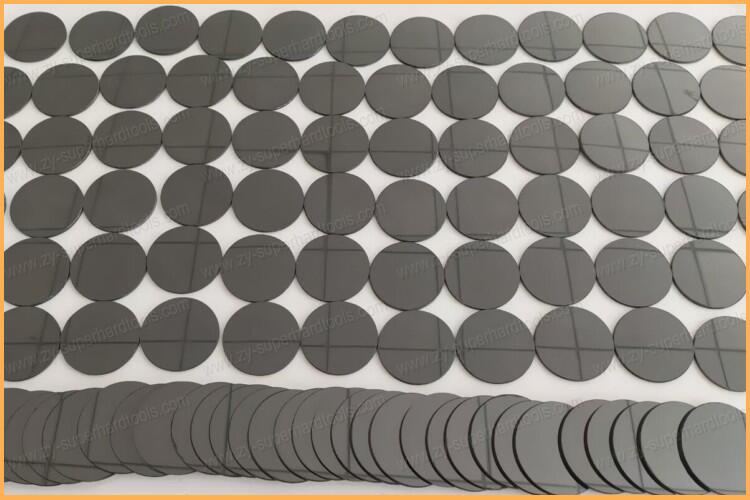

We often divide it into solid cbn and pcbn blanks base with hard alloy.

3. Application of polycrystalline cubic boron nitride tool

PCBN comprises numerous tiny disordered CBN single crystals, no cleavage plane, and is macro directionless, significantly reducing the impact of splitting and continuously exposing new crystals as the cutting tool wear. PCBN and PCD, PCD tool materials have similar structures and properties, but the wear resistance is worse than PCD and PDC. Because of good chemical corrosion resistance, when at 1200℃ high temperature, it shows good thermal stability, so the tool surface will not have any adverse effect on it; on the contrary, it can have a high-speed cutting in cutting hard ferroalloy. With the continuous development of cutting technology, we can widely use cubic boron nitride tools to process high-hardness and complex materials; applications are as follows,

3-1 Because the cubic boron nitride tool has higher hardness and wear resistance, it can apply for grinding hard, turning high hardness challenging to process materials.

3-2 Suitable for high-speed and ultra-high-speed machining

PCBN tool is most suitable for high-speed cutting of cast iron, hardened steel, and other materials. When the PCBN cutting tool is cutting cast iron and hardened steel, according to the tool wear and cutting distance, the cutting speed is higher, the PCBN tool abrasion is lower, and the tool life is longer. This feature is especially suitable for modern high-speed cutting.

3-3 Dry cutting, Coated or ceramic cutting tools need wet cutting; iron chips are not easy to clean. The advantages of using cubic boron nitride tool are that (a) Large margin cutting high-hardness cast iron, (b) do not add cutting fluid, (c) it ensures the site health, (d) it can be recycled iron chips

3-4 Suitable for automatic processing and processing of complex materials

With high hardness and wear resistance, PCBN cutter can process high-precision parts at high cutting speed for a long time, significantly reducing the number of tool changes and tool wear compensation time spent in shutdown. Therefore, the PCBN tool is very suitable for CNC machine tools and a high degree of automation of the processing equipment, and can make the efficient equipment get full play.

4. About the service life of polycrystalline cubic boron nitride

The life of the PCBN tool is 3-5 times that of a ceramic mechanism and 5-15 times that of a complex alloy tool. High wear resistance and long life greatly improve the machining accuracy of the workpiece, reduce the number of tool changes and sharpening, and improve efficiency. With the rapid development of CNC machining technology, many advanced cutting concepts have been introduced, such as high-speed cutting, complex machining, the turning replacement of grinding, and dry cutting. PCBN tool material has become an indispensable tool material in modern cutting.

Contact: Nina Qiao

Phone: 86-13526572721

E-mail: cutting@zy-superhardtools.com

Whatsapp:86-13526572721

Add: AUX Industry,Zhengzhou City,Henan Province,China

We chat