Hardened steel bearing hardness above HRC60, such as wind power bearings, metallurgical bearings, rotary bearings, and hub bearing units, are all hardened steel parts.

Quenched steel bearing is difficult to cut because of their high hardness, low thermal conductivity, and brittleness. Still, suppose you choose the suitable tool material, geometric tool parameters, and cutting parameters and master the operation technology. Workers can cut it to achieve the required machining accuracy and surface quality in that case. With the successful development of new cubic boron nitride tool materials, hard turning (grinding instead of turning) bearings has become the norm.

After heat treatment, the hardness of the bearing reaches HRC60 and above are wind power bearing, slewing bearing, metallurgical bearing, automotive hub bearing, and others.

Wind power generation is the most mature technology in the global renewable energy field, with the most potential development prospects. Green development is an important measure to promote economic structural adjustment, and it also drives the development of the large-scale slewing-bearing and wind power-bearing machinery industry.

Slewing bearing is a significant bearing that can withstand the total load. Slewing bearing is called "the joint of the machine." It comprises an inner ring, an outer ring, and a rolling body. Among them, wind power bearing also belongs to slewing bearing, but wind power generation belongs to a particular new energy industry. Generally, people are used to calling wind power bearings.

The diameter of wind power bearings is more than one meter or even nearly three meters; after heat treatment, there are more or fewer deformation problems, coupled with its hardness HRC55 above, which brings significant challenges to the hard car cutter -CBN blade.

We can provide various cubic boron nitride CBN tools for this kind of hardened steel bearings.

Such as wind power bearings, Generally, the deformation is large after heat treatment

, and large cutting allowance, then recommend CBN-H200 material, CBN-S200 material, and CBN-S20 material, which CBN-H200 material belongs to a single-sided compound cubic boron nitride tool, unilateral cutting depth is about 1mm, if the processing allowance > 1mm, CBN-S200 material, and CBN-S20 material are used.

Common material CBN-H200 blade models such as RNMN090300, RCGX120700, and RNMN120700 are relatively common, mainly circular blades, such as RCMX series, RCGW series, RNGN series, RCGO series, single-side overall composite CBN blade, Circular single-side compound punching CBN blade, integral polycrystalline PCBN blade. ZYSUPERHARD can supply customized; not only is the cutting allowance significant, but it can also withstand intermittent cutting and effectively meet customers' needs to reduce costs and increase efficiency.

Such as metallurgical bearings, automotive hub bearings such parts, single side processing allowance is generally within 0.5mm, the use of CBN-H11 DNGA material, CBN-H10 CNGA120408, CNGA120404 material, but also can provide coated CBN blades, so that the tool life improves at least 35%.

Suitable tool model for processing each part of wind power bearing: outer circle commonly used square blade: SNGN120712; Machining end face choose the diamond blade, CNGN120408; Machining surface shoulder choose diamond blade: CNGN120412, CNGN120408; Circular blade: RNGN120400; RNGM090300.

Solution of CBN processing wind power bearing

(1) Processing the surface of wind power bearing

CBN square blade can process the surface of the wind power bearing, and we can obtain a high surface finish.

Commonly used blade models: SNMN150716 or SNGN120712, because they belong to the whole polycrystalline CBN tool, need to be equipped with hardened tool rod CSDNN central tool protection blade.

(2) Processing the shoulder of the wind power bearing surface table

CBN blade processing wind power bearing surface shoulder can significantly improve production efficiency.

Commonly used blade models: CNGN120412 or CNGN120408, equipped with CCLNR/L 90° turning shank

(3) Processing wind power bearing channel parts

CBN circular blade processing wind power bearing channel parts can obtain a higher surface finish; there are two blade models to choose from.

a: Common blade model: RNGN120400 or RNGN090300, equipped with CRDNN center arc turning tool.

b: Commonly used blade model: RCGX120700 or RCGX090700, equipped with CRDCN central arc turning tool.

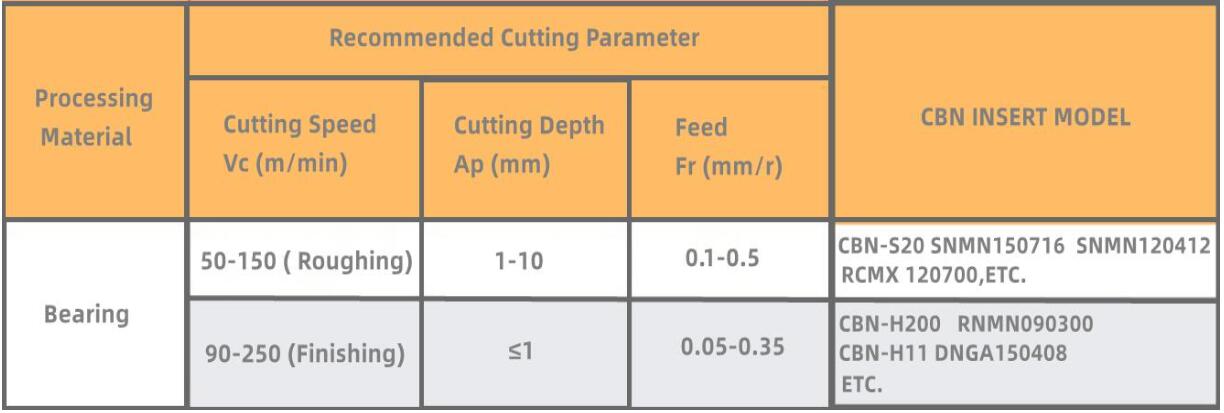

Cutting parameters of cubic boron nitride tool for hard-turning hardened steel bearings

When hard-turning quenched steel bearings, continuous and intermittent cutting can improve the cutting speed. In the face of intermittent cutting, cutting parameters can be lowered slightly, from low cutting to high cutting test, which is safer.

Case parameters for hard turning hardened steel bearings with cubic boron nitride tools

1, CBN-H200 material cubic boron nitride tool hard turning wind power bearing

Processing parts: wind power bearing outer ring raceway (diameter 2750mm)

Workpiece material: 42CrMo4 (hardness HRC58-63)

Surface finish requirement: Ra0.4

Processing procedure: Roughing

Blade model: CBN-H200 RNMN090300

Processing parameters: Vc=190m/min, Fr=0.43mm/r, ap=1mm

Processing procedure: Finishing

2. CBN-H11 material cubic boron nitride tool hard-turning metallurgical bearings

Metallurgical bearings mainly finish the outer circle and inner hole, using inset cubic boron nitride blade CBN-H11 material, high-cost performance, stable cutting performance, and surface finish easily reach Ra0.8

Workpiece hardness: HRC62

Processing parts: bearing outer circle, inner hole

Tool model: CBN-H11 DNGA150408

Cutting parameters: Vc=140m/min, Fr=0.12mm/r, ap=0.5mm

Processing method: dry cutting

3. CBN-H10 C25 material cubic boron nitride tool hard turning automobile hub bearing unit

Hard turning automobile hub bearing unit, using coated cubic boron nitride tool CBN-H10 C25 material, is doubled compared with the traditional tool production efficiency and obtains a higher surface finish.

Processing parts: hub bearing unit,

Workpiece hardness: HRC58-62

Selected blade: CBN-H10 C25

Cutting parameters: Vc=180m/min, Fr=0.1mm/r, ap=0.15mm

Results: When the surface roughness was ≤Ra0.6, the tool life was increased by 45% compared with the uncoated CBN blade.

If you need and don’t know how to choose the suitable cbn inserts,welcome to consult us and tell us your machining request,we will choose the best CBN insert tools for your machining.

In addition,we also supply related cutting drilling tools for wind power bearing oil hole processing,and others.

Contact: Nina Qiao

Phone: 86-13526572721

E-mail: cutting@zy-superhardtools.com

Whatsapp:86-13526572721

Add: AUX Industry,Zhengzhou City,Henan Province,China

We chat