Selection of cutting tools for tungsten carbide roller ring processing

The hard alloy roller ring, also known as tungsten carbide (WC) alloy roller ring, is composed of tungsten carbide and metal bonding phase and trace rare metal elements, at room temperature hardness can reach HRA78~95.

The production process of tungsten carbide roller ring:

Tungsten carbide (tungsten steel) roller rings are produced by powder metallurgy with tungsten carbide powder and cobalt powder (a small amount of other hard phase or alloying elements can also be added) as raw materials. The production process is as follows: alloy preparation - pressing molding - vacuum sintering and HIP hot isostatic pressing - rough grinding - ultrasonic nondestructive testing - fine grinding - grinding hole - grinding round - chamfering machining - grooving (including thread grooving) - laser marking - comprehensive inspection - packaging and storage.

Tools selection for cutting tungsten carbide (tungsten steel) roller rings,

Choosing and using cutting tools reasonably and effectively in production should follow the following principles. First, we should evaluate the entire machining task to meet the workpiece size and surface finish requirements. Considering the processing time and tool replacement rate, select a lower-cost tool to achieve a better machining economy.

The hardness of the carbide roller ring is as high as 83 ~ 85. In the superhard material, the hardness is diamond, cubic boron nitride, ceramics, and hard alloys. Therefore, the primary condition for us to choose a tool is that its hardness must be greater than the hardness of the carbide roller ring. The CBN blade and PCD cutter provided by ZY Super Hard meet customers' processing needs and efficiency.

Due to the high hardness of tungsten steel, roller ring has exceeded the range of traditional cutting tools. Currently, the cutting of tungsten carbide (tungsten steel) roller ring mainly choose PCD tools, and some enterprises also choose CBN tools for cutting tungsten carbide (tungsten steel) roller ring below HRA88.

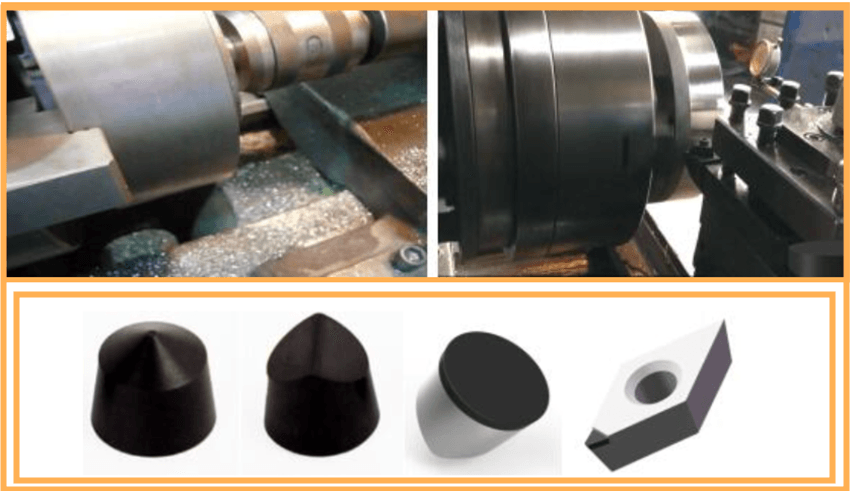

Turning tungsten carbide roller ring with solid cbn or pcbn inserts

Turning is necessary to cut a tungsten carbide (tungsten steel) roller ring. Many enterprises process roller by grinding wheels, but pcd is the preferred material in the turning process. In the turning process, chamfering should be done well in advance, or enough acceptable grinding allowance should be left to avoid the edge collapse problem resulting in scraping the workpiece.

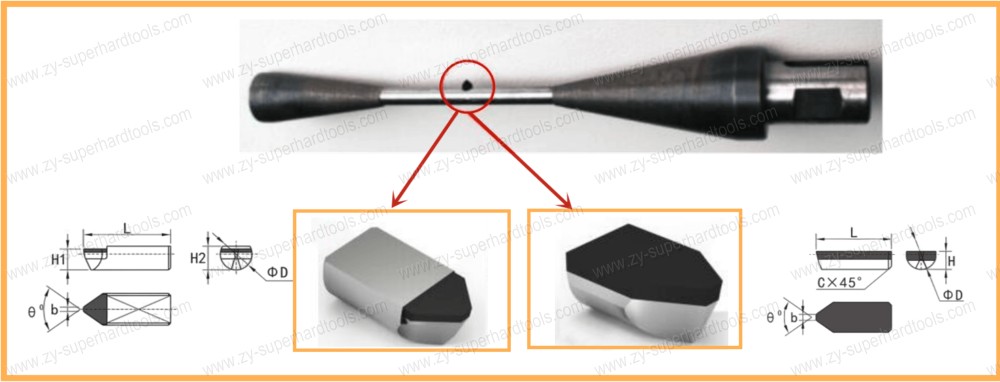

Milling is essential in cutting tungsten carbide (tungsten steel) roller rings, such as the convex bar above the steel bar, called the crescent. These are the roller ring production process done in the model, so the process of milling the crescent is essential, mainly using the PCD rotary milling cutter,we also called it pcd notching tools; as shown below, the middle of the red circle is the position of the diamond blade, by rotating out of a crescent groove.

Milling tungsten carbide roller ring with PCD tool (welding pcd and full-face pcd)

Whether made or repaired, roller rings and processing need PCD rotary milling cutter and pcd inserts; pcd inserts include welding types and full-face pcd structures. For a diameter of 4mm and above (maximum do 9mm more), choose a welding-type structure; for a diameter below 4mm, mainly use the full-face pcd. At the same time, the cutter holder installs 2 pcd milling cutters, which must change to another one after processing for a particular time to prevent fatigue fracture.

When the hardness of the tungsten carbide roller ring is less than HRA88, the integral polycrystalline CBN tool is selected for turning. At the same time, in the turning process, the cutting edge form of the blade is according to the roller ring hardness, machine stiffness, and the user's previous experience to choose; according to the experience, the current cutting edge form is often passivation, chamfering, and passivation.

Case parameters of cutting HRA88 tungsten carbide (tungsten steel) roller ring with CBN inserts such as CBN RNGN120400E,Vc=20m/min,Ap=0.5mm,Fr=1 mm/r.Turning the tungsten carbide roller ring is only recommended for rough processing within HRC88 and, in other cases, recommended pcd tools.

Conclusion: The cold working methods of hard alloy rolls are mainly turning, grinding, crescent milling (rib carving), and lettering.The tool materials used for carbide roll machining are PCBN and PCD. Due to hardness limitations, for rough turning HRA88 hard alloy roll, choose pcbn; PCD tool is used in the fine turning round, chamfering, rib, and engraving.

Contact: Nina Qiao

Phone: 86-13526572721

E-mail: cutting@zy-superhardtools.com

Whatsapp:86-13526572721

Add: AUX Industry,Zhengzhou City,Henan Province,China

We chat