Full Face pcd inserts

Full Surface PCD Polycrystalline Diamond Milling Drilling Inserts

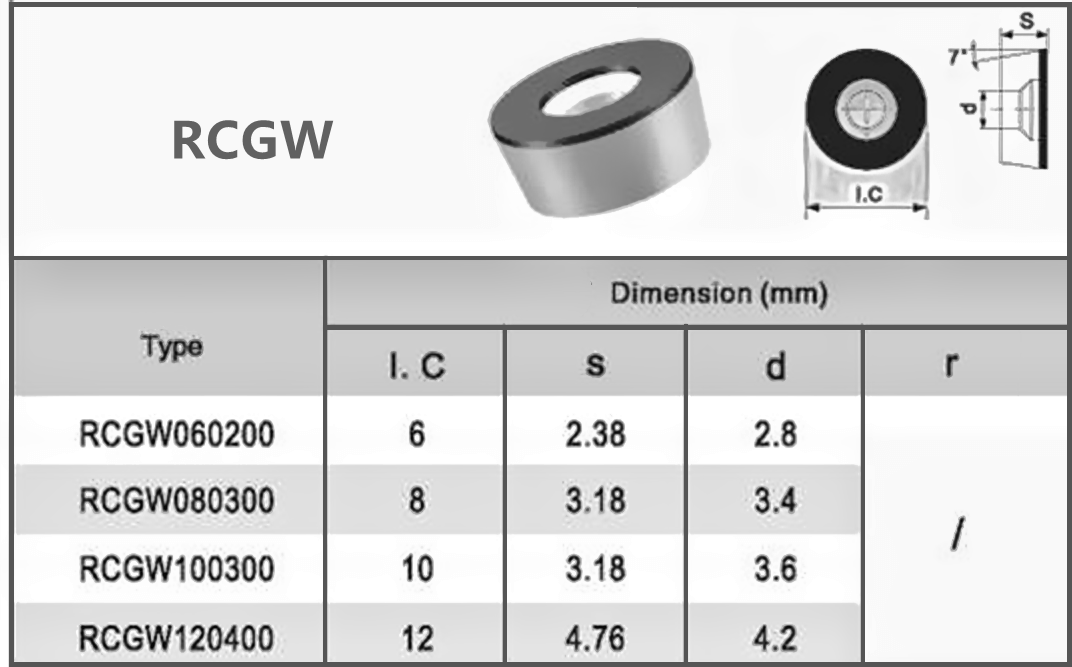

In addition to a layer of poly-crystalline diamond on its insert surface, the full insert is also compounded with a tungsten-based carbide substrate. These pcd inserts help increasing the efficiency of cutting tools. The compound of this tool is circular in shape to maximize the cutting edge and is suitable for specialized products. The wear and tear resistance of these inserts is effective and affects the overall strength.

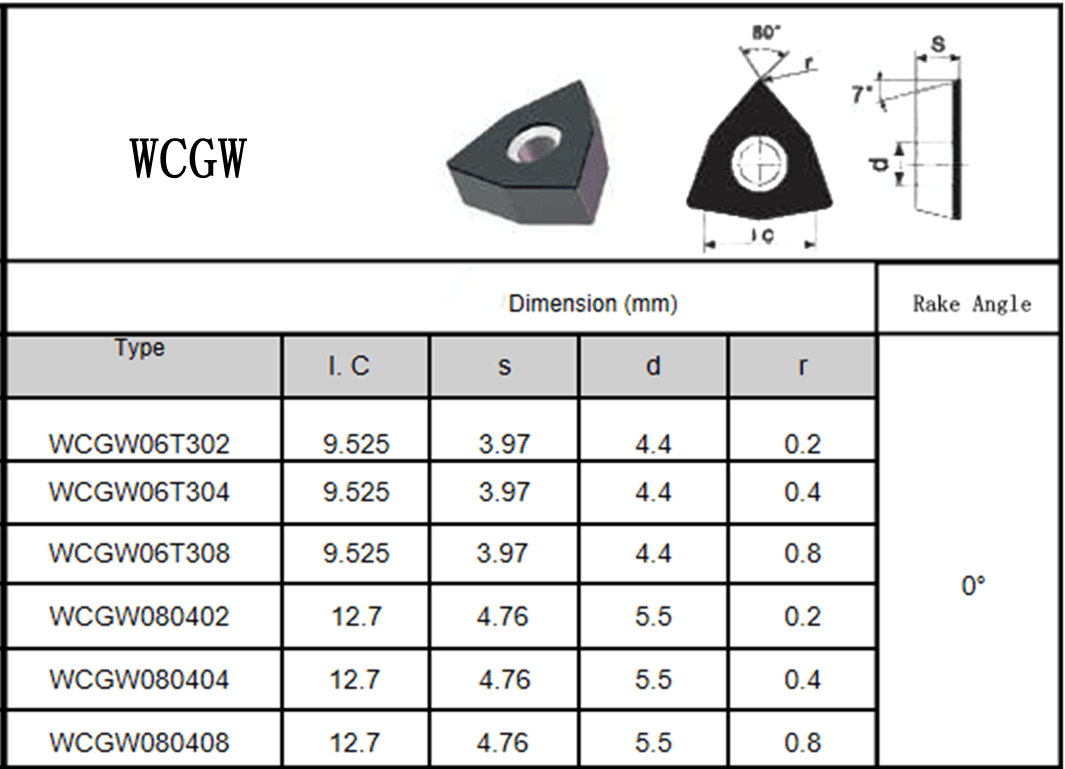

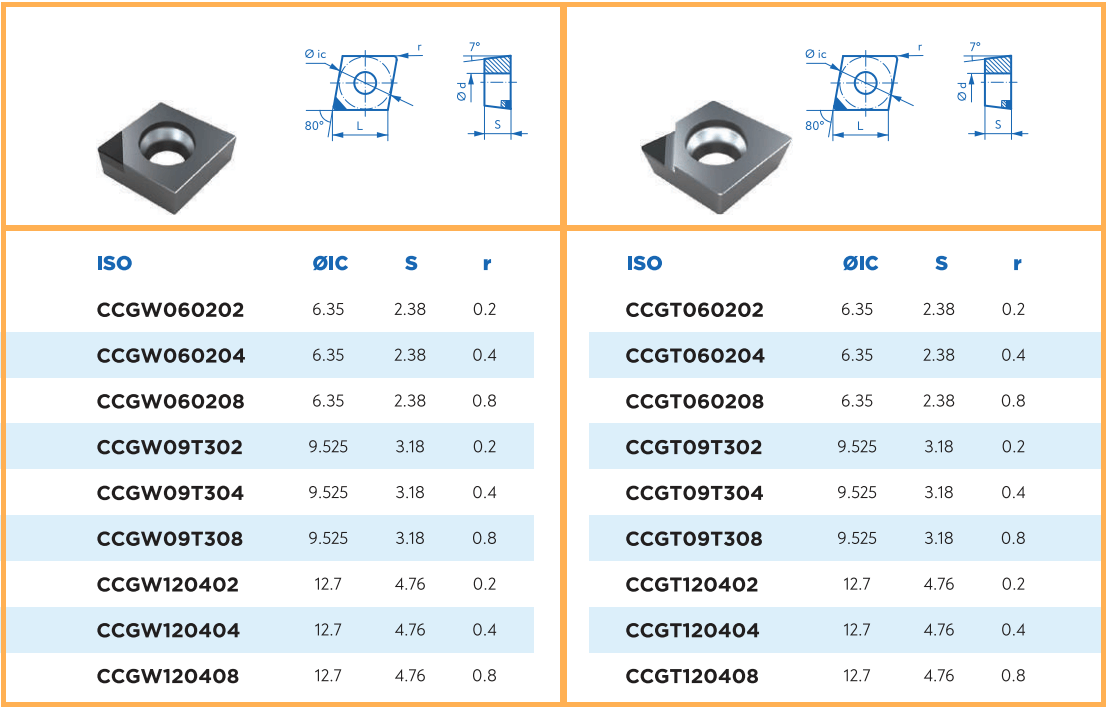

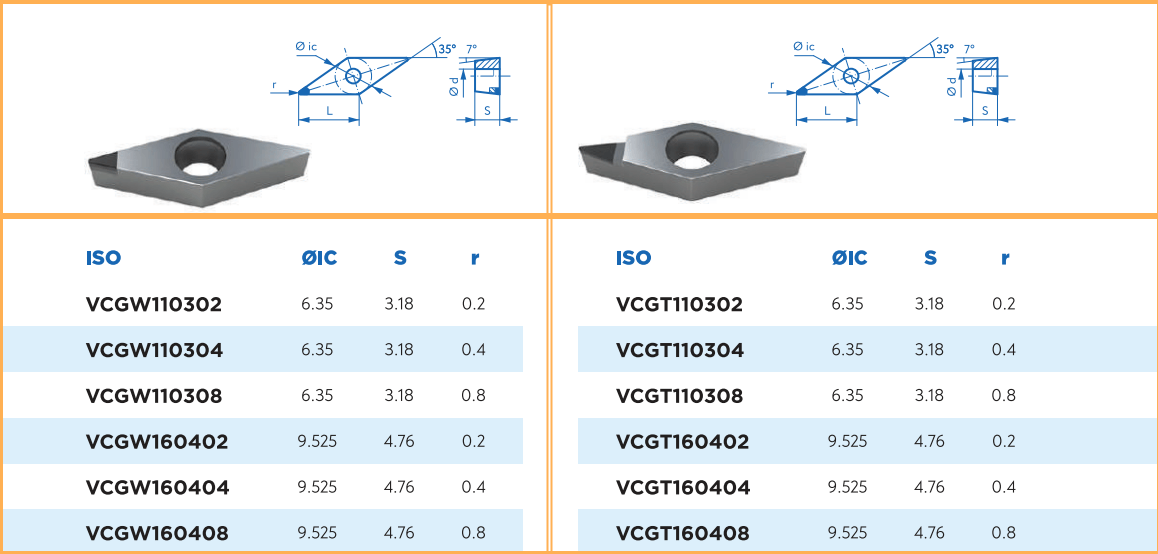

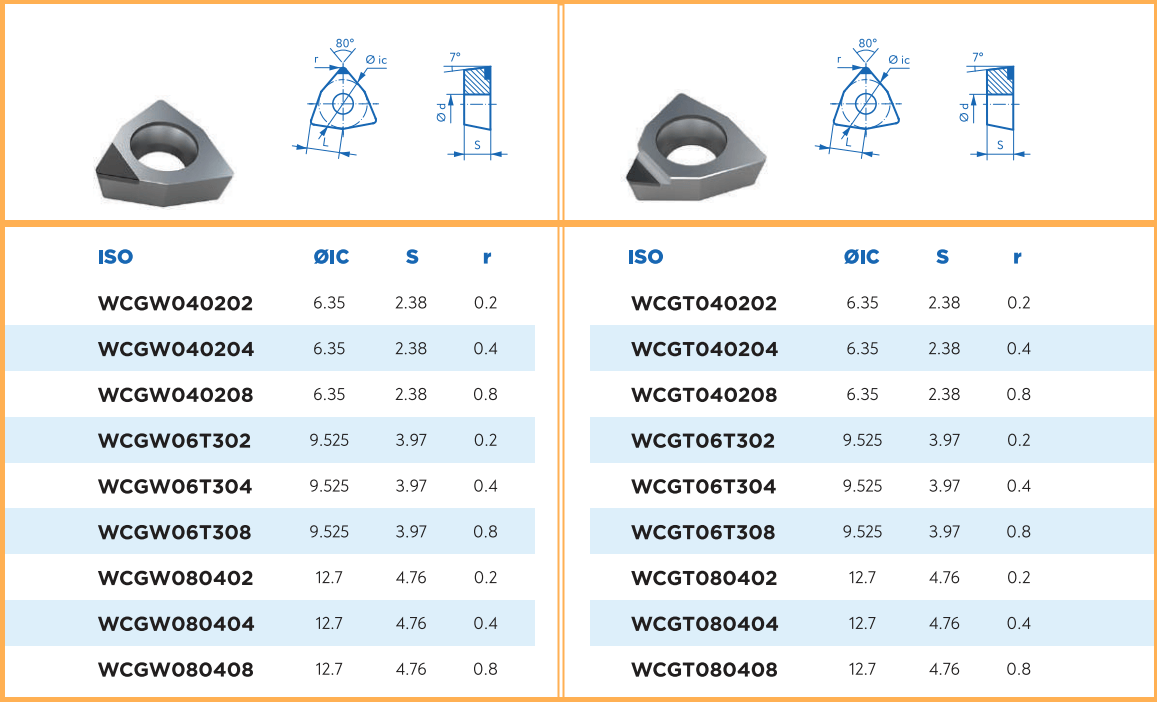

Some type example as follws,

These are widely used in turning ,drilling and milling NC. Compared to other inserts, the full face insert has a higher heating capacity and works better even in harsher temperatures.Full face-milling pcd inserts are used for a variety of purposes, such as surface milling of automotive engine blocks, fine machining of aluminum alloys, cylinder heads and tungsten carbide,drilling wind turbine blade and turning of cast aluminum, non-metallic and copper materials. Some of the advantages of using pcd full face inserts are suitable for large and deep roughing, improve processing efficiency, achieve high precision finishing,increased productivity, higher removal rates, and realize cost economy.

Tipped PCD Inserts For Turning and Milling

The main benefit of using cutting-edge pcd inserts is that they come at a cheaper price and are economical for one time use. Compared to the full blade, it is simpler to manufacture, it only requires a tungsten carbide base carrier as the blade substrate. The substrate has pockets that accommodate and support the tips. The size and structure of the blade vary with the shape of the blade. pcd blades with tips are best suited for ultra-fine precision machining for a good surface finish. Some of the characteristics of the tip blade are that the cutting temperature is limited (no more than 700 degrees) and the working material has no affinity with carbon.PCD cutting edge is very sharp cutting edge blunt radius generally up to 0.1-0.5um.

PCD blades have been widely used in more and more fields, such as: automotive, medical, hydraulic, rail transit, energy, bearing, aerospace, watch manufacturing and other industries.

Therefore, the main uses of pcd blades include processing nonferrous tungsten carbide metal, zinc, copper, aluminum and rubber, wood, plastic and ceramics and other non-metallic materials, mainly for turning pressure tanks.

We supply a complete list to tipped inserts to our customers. We supply pcd inserts in various grades such as for fine finishing,medium finishing ( or standard finishing ) as well as coarse finishing ( for abrasive materials). We also recommend using these tools-with non-metallic as well as metallic materials.

Some Types As Follows,

When ordering PCD inserts, users should correctly grasp the scope of tool adaptation. For example, when processing black metal work-pieces (such as stainless steel) with PCD blades, because the diamond is very easy to react with the carbon element in the steel, it will lead to rapid wear of PCD blades, so the correct choice for processing hardened steel should be PCBN inserts

In general, in order to reduce the cutting force and prevent chip buildup, the PCD inserts should adopt a positive cutting angle. However, when processing high-silicon aluminum alloy (especially when using diamond blades instead of cemented carbide tools for processing), the back Angle of the PCD insert is better than the back angle used by the original cemented carbide tool to slightly reduce, in order to improve the cutting performance of the cutting edge of the PCD blade on high-silicon aluminum alloy. The positive front Angle of the PCD blade should not be too large, because the larger the front angle of the tool, the lower the strength of the cutting edge.

Contact: Nina Qiao

Phone: 86-13526572721

E-mail: cutting@zy-superhardtools.com

Whatsapp:86-13526572721

Add: AUX Industry,Zhengzhou City,Henan Province,China

We chat