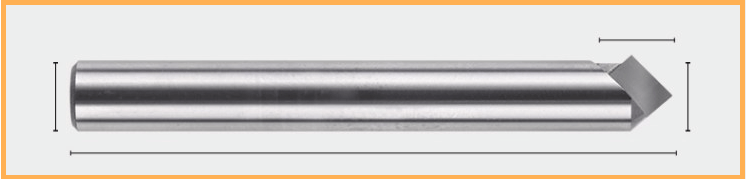

PCD End Mill

End mills are generally used for end milling.Compared with carbide end mill,pcd

(1) The hardness of PCD can reach 8000HV, which is 80 to 120 times that of cemented carbide;

(2) The thermal conductivity of PCD is 700W/mK, 1.5 to 9 times that of cemented carbide, even higher than PCBN and copper, so the PCD tool heat transfer is rapid;

(3) The friction coefficient of PCD is generally only 0.1 ~ 0.3 (the friction coefficient of cemented carbide is 0.4 ~ 1), so the PCD tool can significantly reduce the cutting force;

(4)The thermal expansion coefficient of PCD is only 0.9×10

Sharp, wear resistance, collapse resistance and other properties, more than alloy tools, easy to use and durable, so the overall value is high.

Application: pcd end mill can process non-ferrous metal materials and non-metallic materials, such as non-ferrous metal: aluminum, aluminum alloy, aluminum cast alloy, copper, copper alloy, zinc, zinc alloy and other materials; Non-metallic materials: graphite, carbon fiber composite materials, glass fiber, new composite materials and other materials processing.

Features:

Stable cutting performance

Lasting tool durability

Offer customization services based on specific processing workpieces and working conditions.

Parameters:

| Model | Flute Diameter | Flute Length | Flute No. | Shank Diameter | Total Length |

| D1 | 1 | 3 | 1 | 4 | 50 |

| D2 | 2 | 4 | 1 | 4 | 50 |

| D3 | 3 | 4 | 1 | 4 | 50 |

| D4 | 4 | 4 | 1 | 4 | 50 |

| D5 | 5 | 6 | 2 | 6 | 60 |

| D6 | 6 | 6 | 2 | 6 | 60 |

| D8 | 8 | 6 | 2 | 8 | 75 |

| D10 | 10 | 6 | 2 | 10 | 75 |

| D12 | 12 | 6 | 2 | 12 | 75 |

| Model | Flute Length | Flute No. | Shank Diameter | Total Length |

| R0.5 | 3 | 1 | 4 | 50 |

| R1 | 4 | 1 | 4 | 50 |

| R1.5 | 5 | 1 | 4 | 50 |

| R2 | 6 | 1 | 4 | 50 |

| R3 | 6 | 1 | 6 | 75 |

| R4 | 8 | 1 | 8 | 75 |

| R5 | 8 | 1 | 8 | 75 |

| Model | Flute Diameter | Angle | Flute NO. | Total Length |

| D4 | 4 | 90° | 1 | 50 |

| D6 | 6 | 90° | 1 | 50 |

| D8 | 8 | 90° | 1 | 50 |

| D10 | 10 | 90° | 1 | 50 |

Welcome to purchase if you need pcd end mills,we also supply customized.

Contact: Nina Qiao

Phone: 86-13526572721

E-mail: cutting@zy-superhardtools.com

Whatsapp:86-13526572721

Add: AUX Industry,Zhengzhou City,Henan Province,China

We chat