In recent years, with the development of high-performance, high-precision CNC machine tools, and diamond tools with excellent performance, CNC highlighter machining technology has made a significant breakthrough, and milling instead of grinding has been a mature application. CNC highlight machining principle is in precision CNC machining equipment, using PCD or single crystal highlight diamond tool, with scientific and reasonable cutting parameters and technology to achieve a shining machining surface effect.

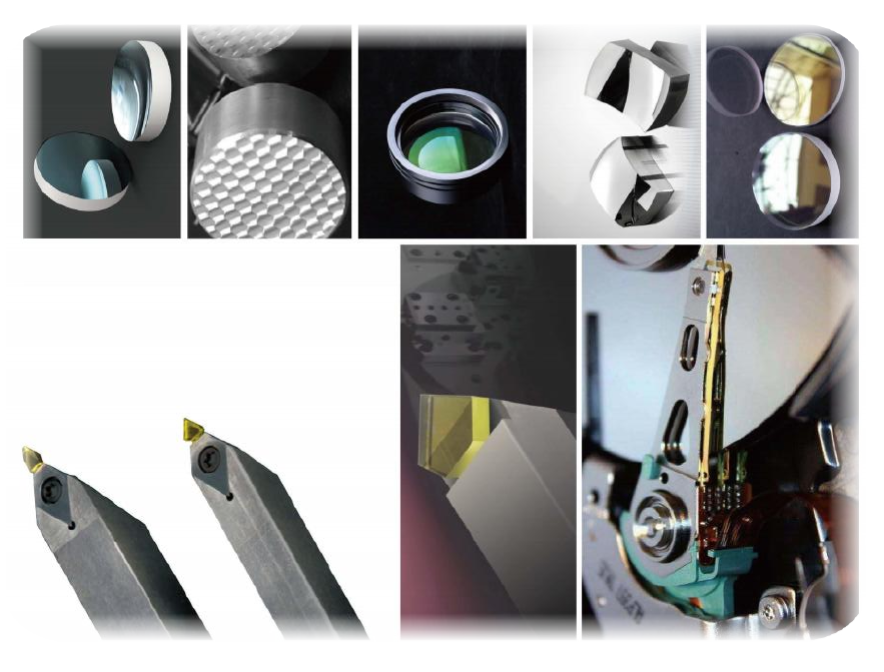

For example, in lens processing, spectacles lenses are generally made of resin, resin lenses are the resin material of optical lenses; glasses lenses are worn on the eyes and can not have defects. Otherwise, it can affect the vision and not be beautiful, so the processing requirements of resin glasses lenses are naturally relatively high.

Resin lenses need to go through more than 10 strict procedures before they can be processed to form the appearance we use. Lens trimming is one of them. Lens trimming makes the lens edge smooth and beautiful and makes the lens curvature needed. In lens finishing, the PCD tools have no scratches, high efficiency, highlight, and other advantages, pcd glasses knife worn out can also be re-grinding to reduce the cost.

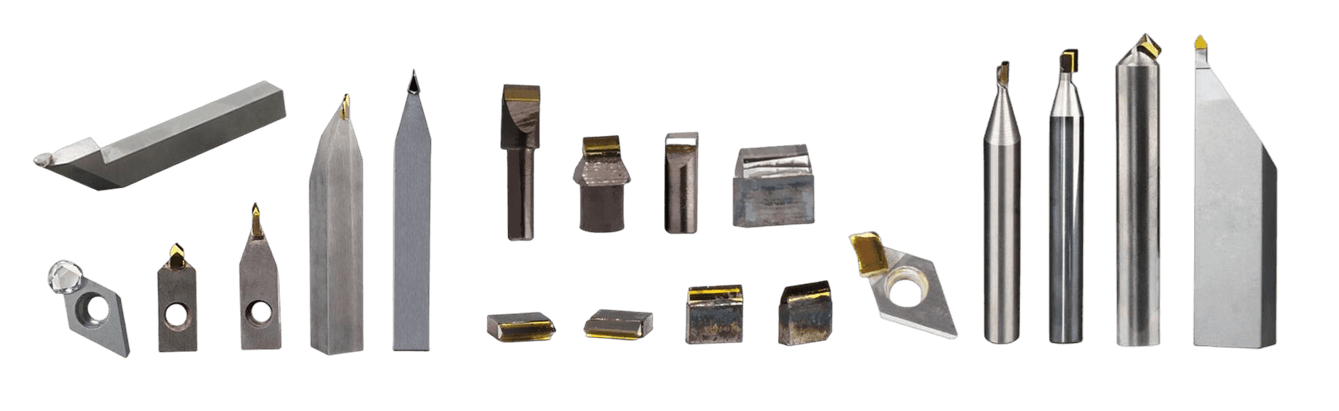

Compared with standard cutting tools, PCD / MCD cutting tools with high hardness, strong wear resistance, high precision, long life, and other characteristics, sharp cutting tools can reduce the odor and dust of resin lens processing, so it also has an advantage in finishing, used to process the lens with no scratches, high efficiency, highlight, and other advantages, can reduce the cost. Whether glasses lens, frame, or frame can be customized according to the thickness of the lens, shape, and others. pcd formed milling cutter for glasses lens, welcome to consult ZYsuperhard.

Acrylic, optical lenses, and 3C electronic products can be used as MCD single crystal highlight tools to obtain an optical mirror's super fine turning effect. High reflectance can be obtained by machining an optical metal mirror with a diamond cutter. In addition to the appearance of computer numerical control (CNC) super finishing lathes in recent years, the contour machining of aspheric mirrors has been solved better.

1. Processing scope of ZY SUPER HARD MCD single crystal diamond tool:

1-1 processing materials: acrylic, plexiglass, copper alloy, copper parts, aluminum alloy, aluminum, die-cast aluminum parts, aluminum parts, copper alloy, copper parts, magnesium alloy, zinc alloy, acrylic, and others.;

1-2 Processing parts: watch shell, mobile phone frame, mobile phone shell, TV shell, camera focusing hardware highlight, mobile phone button, mobile phone camera, mobile phone frame, ring, pendant, speaker, digital camera, 3D complex hardware, hardware decoration pieces, and others.

2. Application industry of ZY SUPER HARD MCD single crystal diamond tool

2-1 Optical lenses industry such as camera lens, dash-cam lens, telephoto lens, medical, mechanical lens, mobile phone lens, projector lens, (non) spherical lens, and Fresnel lens mold processing, Fresnel lens.

2-2 Glasses Industry: glasses lenses, contact lenses.

2-3 Digital electronics industry: TV and computer LCD core accessories optical film ROLL core and plate core processing, mobile phone edge mirror, mobile phone critical button mirror, mobile phone flashlight edge mirror.

2-4 Automobile industry: HUD system, night driving optical system, piston, aluminum hub, aluminum engine cylinder block, and other core parts processing in the automobile manufacturing industry.

2-5 Aerospace industry: Special protective glasses and aircraft Windows for night flight.

2-6 Medical industry: Blood analysis kit and knife for delicate surgery.

2-7 Military Industry

2-8 Other optics: fiber optics, solar panels, semiconductor manufacturing equipment accessories, VR optical components processing.

3. Processing effect advantage of ZY SUPER HARD MCD diamond tool

ZY superhard MCD diamond cutting tool is made of high-grade diamond material with high hardness and wear resistance. The cutting edge is sharp and precise, and the work is satisfactory. CNC machining can not produce knife lines, and the processed surface has a high gloss and can achieve the effect of pure mirrors (the surface roughness is less than Ra0.1). Can meet the work-piece of high-quality processing requirements. And ZYsuperhard natural diamond tool edge using seismic design can inhibit vibration in the process of the processing; at the same time, the use of imported large particle diamond, high durability, enhances the stability in the process of processing to achieve high efficiency, high quality, high stability processing.

Please note: The use of MCD diamond-cutting tools to improve the finish of the surface.

● The use of super hard natural diamond tool processing, as far as possible to use high-speed processing, so the best choice of high precision, small vibration machine tools;

● For work-piece processing, one can first use a PCD cutting tool or alloy cutting tool to do rough machining and then use a natural diamond cutting tool for finishing; the finishing reserve allowance to be minor, and the cutting amount is best controlled within 5 wire, and choose suitable special coolant (recommended water vapor mixing cooling);

● Using natural diamond cutting tools, if the blade is not sharp, no collapse or obvious defects can be returned to the factory for grinding and reprocessing, further extending the tool's service life.

Contact: Nina Qiao

Phone: 86-13526572721

E-mail: cutting@zy-superhardtools.com

Whatsapp:86-13526572721

Add: AUX Industry,Zhengzhou City,Henan Province,China

We chat