SG Grinding Wheels

SG abrasive grinding wheel has the advantages of high hardness, good toughness, strong sharpness, large single feed and many superior advantages. Compared with ordinary corundum grinding wheel, SG grinding wheel has the advantages of high wear ratio, good work-piece surface processing quality, good self-sharpness, sharp grinding, less dressing times and high grinding efficiency. SG grinding wheel paste is suitable for aerospace alloy, special tool steel, bearing steel, hard chrome plated materials, hard cast iron and new hard materials grinding processing, in addition, SG porosity grinding wheel has a good anti-burn effect.

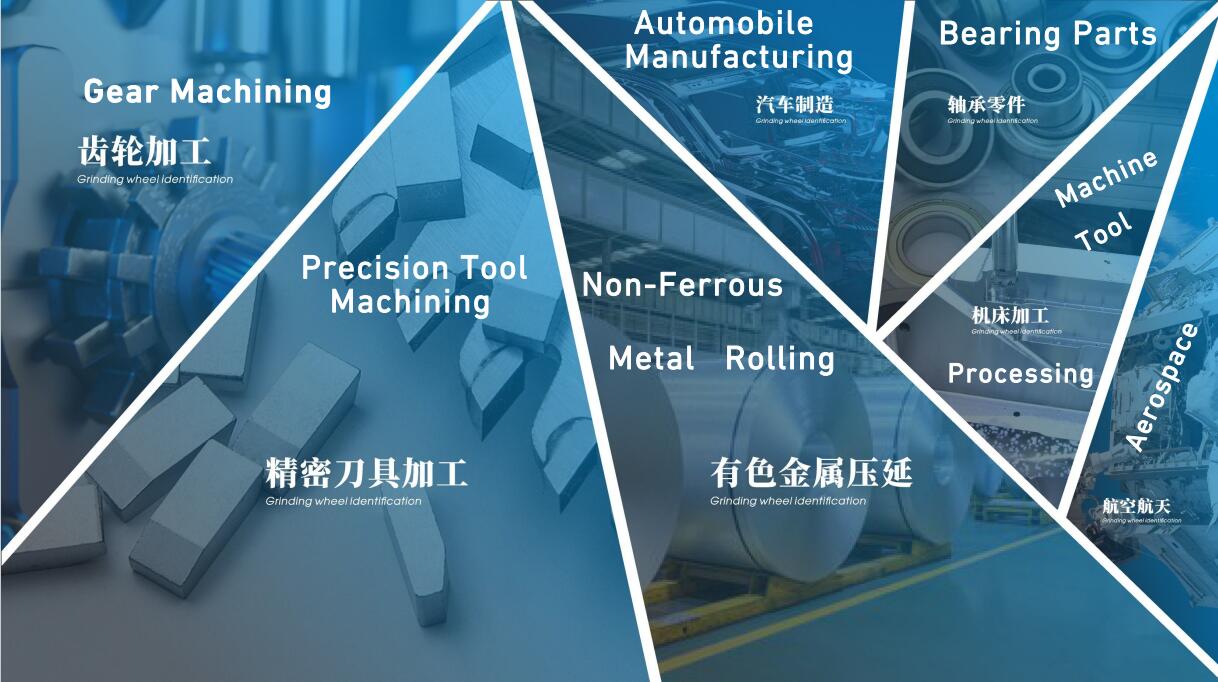

SG grinding wheel due to its excellent characteristics, is widely used in the following fields:

Aerospace alloy: SG grinding wheel is especially suitable for the grinding of aerospace alloy, which can improve the grinding efficiency and reduce the burn on the workpiece surface under the premise of ensuring the processing quality.

Special tool steel and special bearing steel: SG grinding wheels are also suitable for grinding special tool steel and special bearing steel, enabling efficient, high-quality surface machining.

Hard chrome materials and hard cast iron: SG grinding wheel for hard chrome materials and hard cast iron grinding effect is excellent, can avoid the workpiece surface burn, improve the processing quality and efficiency.

New hard grinding materials: SG grinding wheel is also suitable for the grinding of new hard grinding materials, which can achieve efficient and high-quality surface processing.

In the specific application, SG grinding wheel has excellent performance in the field of large gear hard tooth surface forming grinding, worm grinding, roll grinding, machine guide grinding, high-precision ultra-screw grinding, rubber roller grinding and so on.

Gear and worm grinding wheells,application of high performance binder combined with the addition of new alumina ceramic abrasives such as SG and TG, the consumption of dressing tools and dressing time is greatly reduced. The take-off of China's economy has led to the rapid development of mining, wind power generation, automobile manufacturing and other industries, and gear as an important part of mechanical transmission also has a huge market demand.

The introduction of imported molding gear grinding machines such as HOFLER, NILES, GLEASON, etc. for large gear processing, SG abrasive has attracted wide attention from the domestic industry with its excellent grinding performance. In 2008, our company independently developed the first generation of LG low-temperature bond suitable for SG abrasive manufacturing, and put into mass production, and obtained market recognition.

Arc gear grinding wheel is suitable for different materials and precision machining requirements, whether WA,SA, or SG,TG can providecustomers with satisfactory products.

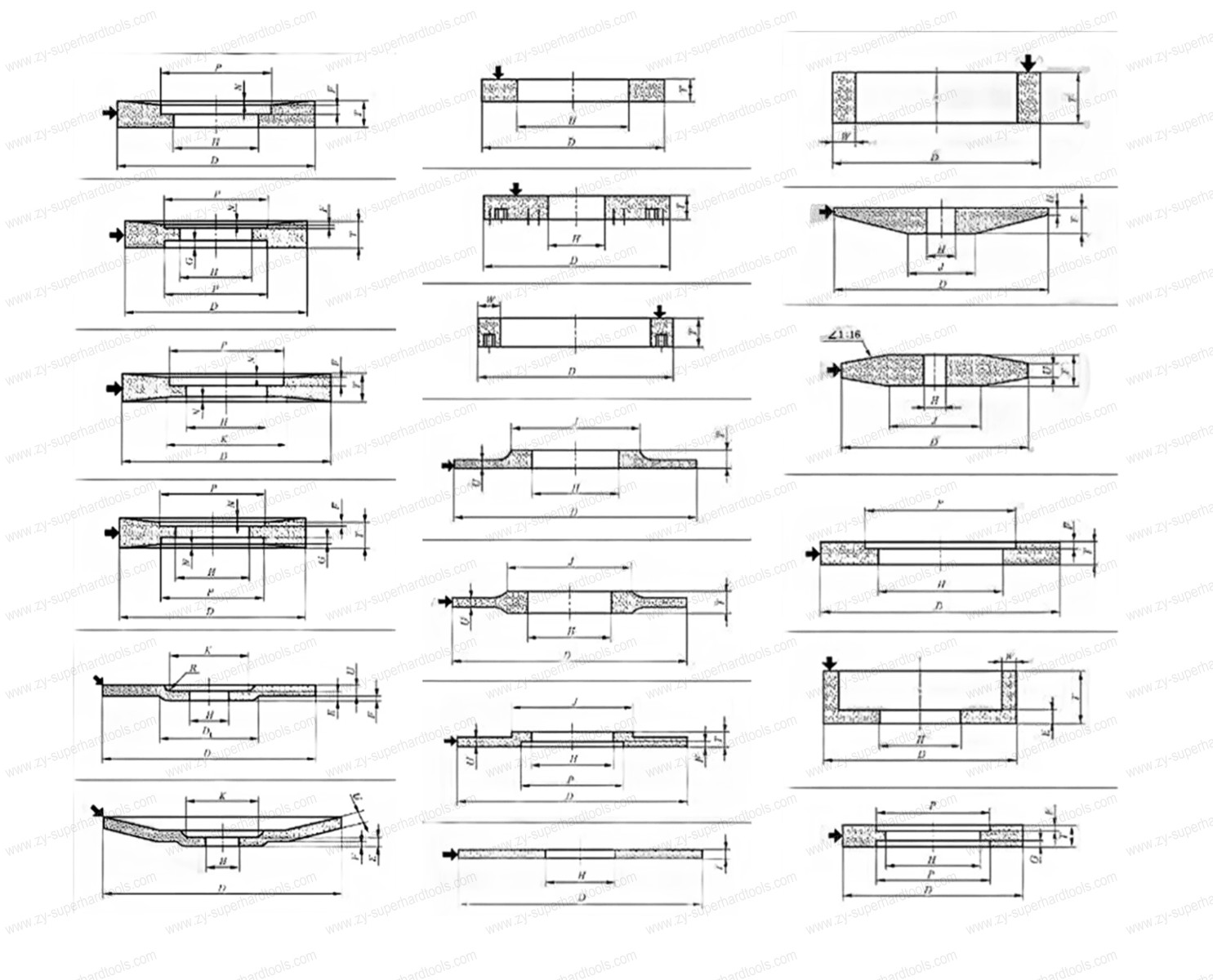

Standard Wheel Types As Follows,

Contact: Nina Qiao

Phone: 86-13526572721

E-mail: cutting@zy-superhardtools.com

Whatsapp:86-13526572721

Add: AUX Industry,Zhengzhou City,Henan Province,China

We chat