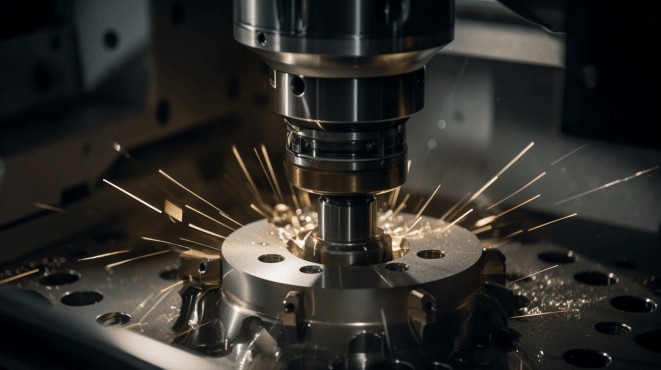

In aerospace, achieving a superior surface finish is crucial for producing high-quality components. Poly-crystalline Diamond (PCD) cutting tools have emerged as a game-changer in machining operations, offering exceptional performance and precision. This article discusses the advantage and applications of PCD cutting tools, highlighting their significance in attaining superior surface finishes.

1. Introduction

The aerospace industry demands precise and flawless machining operations to meet stringent safety, efficiency, and performance requirements. Surface finish plays a vital role in determining the quality and functionality of aerospace components. PCD cutting tools have revolutionized the industry by offering exceptional performance and superior surface finishes.

2. Understanding PCD Cutting Tools

PCD cutting tools are made from a synthetic diamond material known as Poly-crystalline Diamond. They consist of a diamond layer bonded to a carbide substrate, combining the diamond's hardness with the carbide's toughness. This unique combination results in a highly resistant tool to wear and abrasion, allowing for extended tool life and consistent performance.

3. Advantages of PCD Cutting Tools

PCD cutting tools provide several advantages over conventional cutting tools:

a. Exceptional Hardness and Wear Resistance

The diamond layer in PCD cutting tools offers exceptional hardness, making them highly resistant to wear and abrasion. This hardness allows for prolonged tool life and reduces the need for frequent tool changes, resulting in increased productivity and cost savings.

b. Superior Surface Finish

Due to their ultra-fine cutting edges and excellent dimensional stability, PCD cutting tools can achieve superior surface finishes. They produce smooth and precise cuts, minimizing the need for post-machining operations and enhancing the overall quality of the machined components.

c. Enhanced Heat Dissipation

PCD cutting tools have excellent thermal conductivity, allowing efficient heat dissipation during machining. This feature prevents heat-related issues such as thermal expansion and helps maintain dimensional accuracy, contributing to achieving superior surface finishes.

d. Chemical Inertness

PCD cutting tools are chemically inert, making them highly suitable for machining composite materials commonly found in the aerospace industry. They resist chemical reactions and do not form built-up edges, ensuring consistent cutting performance and improved surface finish.

4. Applications of PCD Cutting Tools

PCD cutting tools find extensive applications in the aerospace industry, including:

a. Machining Aluminum Components

Aluminum is a widely used material in aerospace manufacturing. PCD cutting tools excel in machining aluminum due to their high wear resistance and excellent chip control. They enable high-speed machining while maintaining superior surface finishes on aluminum components.

b. Cutting Composite Materials

Composite materials, such as carbon fiber-reinforced polymers (CFRP), are increasingly used in aerospace applications. PCD cutting tools, with their chemical inertness and sharp cutting edges, are ideal for achieving precise cuts and superior surface finishes on composite materials. They minimize delamination and fiber pullout, resulting in high-quality machined parts.

c. Finishing Operations

PCD cutting tools are highly effective in finishing operations, where achieving exceptional surface finishes is critical. Whether de-burring, chamfering, or contouring, PCD tools provide the precision and consistency needed to obtain superior surface finishes on aerospace components.

d. Machining Hardened Steels

In certain aerospace applications, the machining of hardened steels is required. PCD cutting tools, with their exceptional hardness and wear resistance, can effectively cut through hardened steels while maintaining the desired surface finish and dimensional accuracy.

5. Factors Affecting Surface Finish

Several factors can impact the surface finish achieved with PCD cutting tools. These include:

a. Cutting Parameters

Optimizing cutting parameters such as cutting speed, feed rate, and depth of cut is crucial for obtaining superior surface finishes. Proper parameter selection ensures efficient chip evacuation, minimizes tool vibration, and prevents workpiece deflection, improving surface quality.

b. Tool Geometry

The geometry of PCD cutting tools, such as the rake angle, clearance angle, and cutting edge design, can influence surface finish. Choosing the appropriate tool geometry for specific machining operations is essential to achieve the desired surface quality.

c. Workpiece Material

Different materials have varying machinability characteristics. PCD cutting tools are particularly effective for machining non-ferrous materials like aluminum and composites. However, alternative tooling solutions may be required to achieve superior surface finishes when working with other materials, such as titanium or stainless steel.

d. Tool Wear

As PCD cutting tools wear over time, their performance may decline, potentially impacting the achieved surface finish. Regular tool inspection and replacement are necessary to maintain consistent cutting performance and high-quality surface finishes.

6. Achieving Superior Surface Finish with PCD Cutting Tools

To achieve superior surface finishes with PCD cutting tools, consider the following steps:

Step 1: Proper Tool Selection

Choose the appropriate PCD cutting tool based on the machining requirements and workpiece material. If applicable, consider factors such as tool geometry, cutting edge sharpness, and coatings to optimize surface finish.

Step 2: Optimize Cutting Parameters

Fine-tune cutting parameters such as cutting speed, feed rate, and depth of cut to achieve the best balance between material removal rate and surface finish. Conduct tests and make adjustments to find the optimal parameters for your specific application.

Step 3: Maintain Rigidity and Stability

Ensure the machine tool and workpiece setup provides rigidity and stability during machining operations. It minimizes tool vibration, workpiece deflection, and other sources of surface imperfections, resulting in superior surface finishes.

Step 4: Implement Effective Cooling and Lubrication

Proper cooling and lubrication during machining help dissipate heat, prevent tool overheating, and maintain dimensional accuracy. Use suitable coolants and lubricants compatible with PCD cutting tools and the workpiece material.

Step 5: Monitor Tool Wear

Regularly inspect PCD cutting tools for signs of wear or damage. Replace worn tools promptly to maintain consistent cutting performance and achieve the desired surface finish.

7. Best Practices for Using PCD Cutting Tools

To maximize the benefits of PCD cutting tools and achieve superior surface finishes, follow these best practices:

Conduct thorough research and consult with tooling experts to select the right PCD cutting tools for your application.

Optimize cutting parameters based on the machined material and the desired surface finish.

Implement effective chip evacuation techniques to prevent chip re-cutting and surface damage.

Employ suitable cutting fluid or coolants to enhance tool life and maintain surface quality.

Regularly inspect and maintain PCD cutting tools to ensure optimal performance.

Invest in proper training and education for operators to handle PCD cutting tools correctly.

Monitor and analyze machining data to identify areas for improvement and optimize processes.

Stay updated with advancements in PCD cutting tool technology and industry best practices.

By following these best practices, aerospace manufacturers can harness the full potential of PCD cutting tools and achieve superior surface finishes, resulting in high-quality, reliable, and efficient aerospace components.

8. Maintenance and Care of PCD Cutting Tools

It is essential to implement proper maintenance and care practices to prolong the life and performance of PCD cutting tools. Here are some recommendations:

Clean the tools after each use to remove chips, debris, and coolant residue.

Inspect the cutting edges for wear and damage regularly.

Sharpen or replace tools as needed to maintain optimal cutting performance.

Store PCD cutting tools in a clean and dry environment to prevent corrosion.

Follow manufacturer guidelines for reconditioning or recoating PCD tools.

Provide proper training to operators on tool handling and maintenance procedures.

Collaborate with tooling suppliers to develop a maintenance schedule tailored to your needs.

Implementing a comprehensive maintenance plan for PCD cutting tools ensures prolonged tool life, consistent performance, and optimal surface finishes in aerospace machining operations.

9. Challenges and Limitations of PCD Cutting Tools

While PCD cutting tools offer numerous advantages, they also have certain challenges and limitations to consider:

Initial Cost: PCD cutting tools can be more expensive upfront than conventional ones. However, their extended tool life and superior performance often justify the investment.

Brittle Nature: PCD cutting tools are susceptible to chipping and fracturing if subjected to excessive force or impact.Careful handling and appropriate machining techniques are necessary to avoid tool damage.

Material Compatibility: While PCD tools excel in machining non-ferrous materials and composites, they may not be optimal for all materials. Machining harder materials like stainless steel or super alloys may require alternative tooling solutions.

Resharpening Limitations: PCD cutting tools have a finite number of resharpening cycles due to the limited thickness of the diamond layer. After multiple resharpenings, the tool may need to be replaced.

By understanding and mitigating these challenges, manufacturers can effectively leverage the capabilities of PCD-cutting tools while minimizing limitations.

10. Future Developments in PCD Cutting Tools

As technology advances, continuous improvements are being made in PCD cutting tools to enhance their performance and surface finish capabilities further. Some notable areas of development include:

Advancements in Diamond Coatings: Researchers are exploring new diamond coatings and deposition techniques to improve tool life, reduce friction, and enhance surface finish.

Customized Tooling Solutions: Tailor-made PCD cutting tools designed for specific aerospace applications are increasingly prevalent, optimizing performance and surface finish in complex machining operations.

Multi-Layered PCD Tools: Innovations in multi-layered PCD cutting tools, combining different diamond grain sizesor introducing inter layers, are being pursued to achieve even higher levels of surface finish and wear resistance.

Integration with Industry 4.0 Technologies: PCD cutting tools are being integrated with data-driven technologies, such as real-time monitoring and predictive analytics, to optimize tool life, surface finish, and overall machining efficiency.

These future developments hold great potential for further enhancing the capabilities of PCD cutting tools, enab ing aerospace manufacturers to achieve superior surface finishes with even greater precision and efficiency.

11. FAQs

11-1. Are PCD cutting tools only suitable for the aerospace industry?

While PCD cutting tools are widely used in the aerospace industry, they are also employed in various other industries such as automotive, electronics, and medical. Their exceptional performance makes them versatile for machining non-ferrous materials and composites.

11-2. Can PCD cutting tools be resharpened?

Yes, PCD cutting tools can be resharpened. However, there is a limit to the number of resharpening cycles due to the limited thickness of the diamond layer. After multiple resharpening, the tool may need to be replaced.

11-3. How do PCD cutting tools contribute to productivity improvements?

PCD cutting tools offer extended tool life, reducing the need for frequent tool changes. It results in increased productivity, reduced downtime, and cost savings. Additionally, their superior surface finish capabilities minimize the need for post-machining operations, further enhancing productivity.

11-4. Can PCD cutting tools handle high-speed machining?

Yes, PCD cutting tools are well-suited for high-speed machining. Their exceptional hardness and thermal conductivity allow for efficient heat dissipation, reducing the risk of tool overheating and maintaining dimensional accuracy even at high cutting speeds.

11-5. Where can I get PCD cutting tools for aerospace machining?

Several reputable tooling suppliers and manufacturers specialize in PCD cutting tools for aerospace machining. It is recommended to research and consult with experts to find the most suitable supplier for your specific needs.

Contact: Nina Qiao

Phone: 86-13526572721

E-mail: cutting@zy-superhardtools.com

Whatsapp:86-13526572721

Add: AUX Industry,Zhengzhou City,Henan Province,China

We chat