Welcome aboard! Do you have a curiosity about PCD tools? Are you intrigued by the 3C industry? If so, buckle up, as this article can guide you through an enlightening exploration of PCD tools' role in the 3C industry. We'll also tackle the benefits they provide and the trends impacting their future. Shall we get started?

Polycrystalline Diamond, or PCD, is a super-hard material that is heavily used in industrial sectors. Made by sintering selected diamond particles with a metal matrix, PCD tools are high-performance cutting tools.

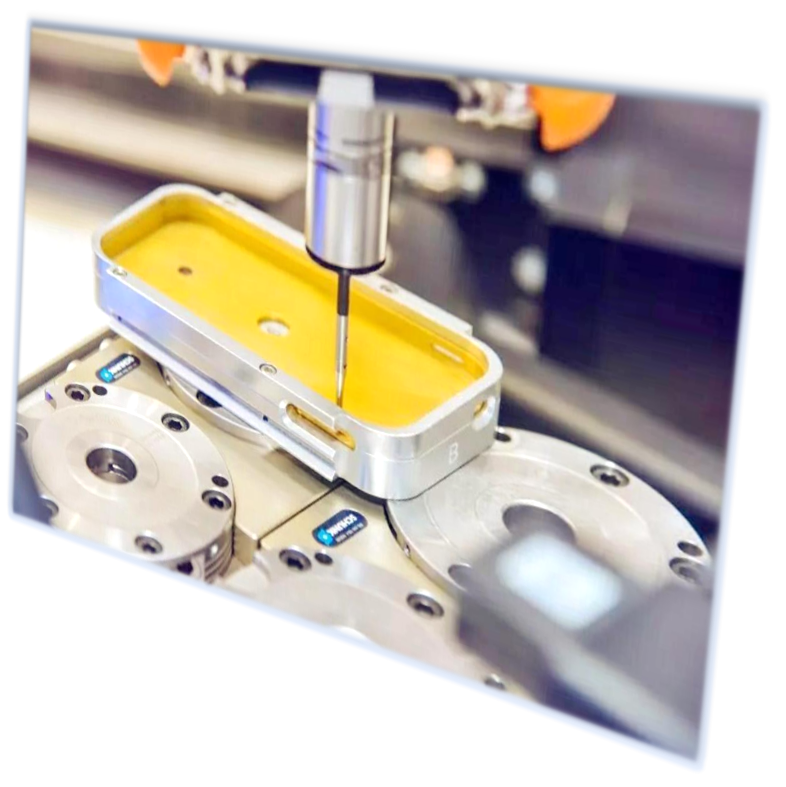

PCD tools boast a dual-layer structure: a working layer containing polycrystalline diamonds and a carbide base layer. These tools are manufactured under high-temperature and high-pressure conditions, giving them impressive strength and hardness.

The 3C industry stands for Computers, Communications, and Consumer Electronics. It is a domain that has seen a massive growth spurt in recent decades owing to rapid technological advancement and digitalization.

PCD tools are vital cogs in the 3C industry, used extensively in manufacturing computers, communication devices, and consumer electronics. Their exceptional precision and durability make them indispensable.

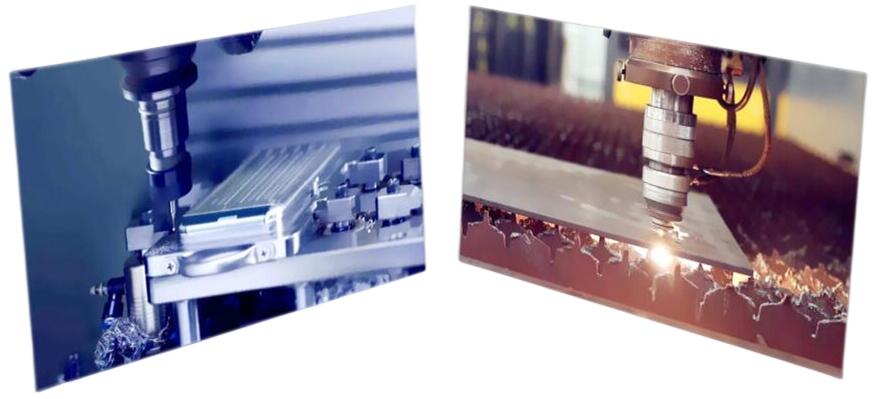

From creating specific components to drilling intricate holes in motherboards, PCD tools play a key role in computer manufacturing. Their superb cutting abilities help shape technology as we know it.

PCD tools are also employed in communication technology. They're essential in crafting fiber optics, connectors, and various other integral components that shape our connected world.

From smartphones to gaming consoles, PCD tools are crucial in crafting consumer electronics that enrich our daily lives. They ensure the highest manufacturing quality, delivering products we all rely on.

PCD tools offer extraordinary precision, making them essential for manufacturing intricate and delicate 3C products. Their efficiency is unparalleled, contributing to increased productivity and reduced wastage.

Because of the high hardness and wear resistance, PCD tools can withstand demanding manufacturing conditions, providing superior durability and longer tool life.

While PCD tools might have a higher upfront cost, their longevity and efficiency make them a cost-effective solution in the long run.

The 3C industry continues to evolve, and the demand for advanced PCD tools grows. With advancements in artificial intelligence, IoT, and 5G, the future looks bright for PCD tools in this sector.

Technological advancements may give rise to more durable, efficient, and precise PCD tools. Innovations in manufacturing processes might also improve their affordability, further expanding their applications.

PCD tools are truly the backbone of the 3C industry. From precision to durability, they offer many benefits, making them a vital part of our technological landscape. As we march towards a technologically advanced future, their role is set to become even more significant.

1. What does PCD stand for? Polycrystalline Diamond.

2. What are some applications of PCD tools in the 3C industry? PCD tools are used for machining computer parts, communication devices, and consumer electronics.

3. What are the benefits of PCD tools? PCD tools offer high precision, durability, efficiency, and cost-effectiveness.

4. How do PCD tools contribute to the future of the 3C industry? With technological advancements, the demand for more sophisticated PCD tools is likely to increase.

5. What does the 3C industry include? The 3C industry includes Computers, Communications, and Consumer Electronics.

Contact: Nina Qiao

Phone: 86-13526572721

E-mail: cutting@zy-superhardtools.com

Whatsapp:86-13526572721

Add: AUX Industry,Zhengzhou City,Henan Province,China

We chat