The energy industry has become a hot topic, and people have been concerned about its development. In addition to the traditional energy industry, wind power, nuclear power, solar energy and tidal energy, and other emerging clean energy are more and more people's attention;the rapid development of the energy industry on its related manufacturing also put forward higher requirements, among which, the cutting tool is one of the most critical factors, under the ensuring processing quality and production efficiency of the premise, for the energy industry, especially the new energy industry, How enterprises should choose suitable cutting tools is what we must be concerned about.

Cutting tool selection is a very analytical work, and each new project is like a reasoning topic; you need to use deduction and induction to get the most suitable product; in short, it is a continuous disassembly and combination process. The customer's parts are particular things, and you have to break this into as small and detailed properties as possible; each property impacts the tool's design, and then summed up these effects, you can get the product you need.

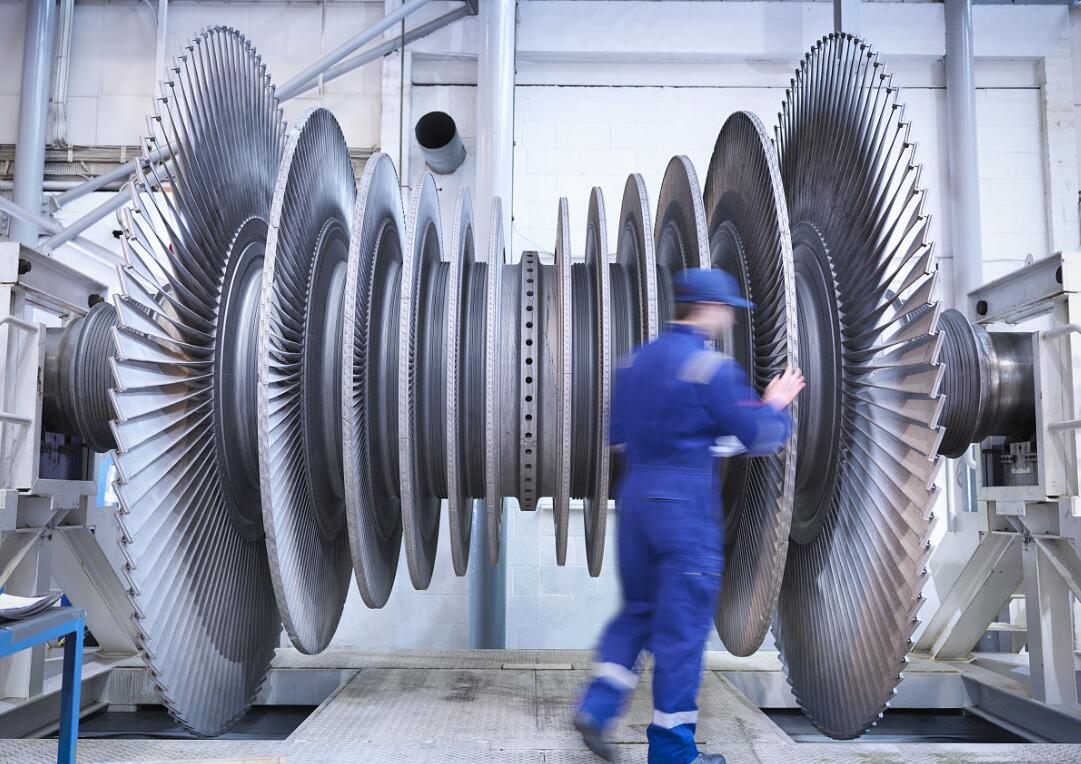

For example, in the processing of turbine blades, fan blade mold, and a 5MW fan, the blade can reach 60m long and 5m wide; the corresponding mold is also quite large: from a geometric point of view, the large volume requires rapid removal of margin, ZY super hard's Mill series insert milling cutter tools can be fast metal cutting under high-speed feed conditions. In the process of metal cutting, a significant length may cause the tool to overhang; In the case of a long overhang, to quickly remove the allowance, it is necessary to reduce the cutting resistance; In the case of a long overhang, it is easy to produce vibration, which requires the cutting edge to have substantial impact resistance and good toughness; There is a space surface on the blade, so the tool needs to have arc elements. The following results can be obtained: ZY-superhard tools can be used for rapid surface milling, cavity roughing, deep cavity copying roughing, and finishing the cavity with a round blade.

For example, the blade of the turbine, the blade material used in the high-temperature and high-pressure inlet end of the steam turbine of the thermal power station, is a high-temperature alloy, the material itself has high strength and toughness, and the plastic deformation of the surface during processing has severe work hardening, making the chips solid and challenging. Hence, the cutting force is large, and the cutting temperature is high. The cutting resistance is reflected in the tool design, and the cutting force should be reduced by increasing the front Angle and back Angle of the tool. Suppression of the effect of cutting temperature can be achieved by knowledge of tool coatings, which slow the impact of temperature by inhibiting the heat transfer from the cutting zone to the blade (tool), acting like a heat insulation film because it has a much lower heat transfer coefficient than the tool base and work-piece material. We can provide the corresponding super hard tools for super-alloys designed for this challenging material PVD, nitride titanium carbide coating.

The shape of parts in the energy industry has a standard feature that is large, and the work piece material is characterized by the processing of steel, stainless steel, and super-alloy, so fast metal cutting. A complete product line is necessary to meet the processing of large parts.

For non-metallic materials in the wind power industry, such as glass fiber, carbon fiber, and synthetic resin composite materials, our poly-crystalline diamond tools, as well as small waveform blade tools, can effectively prevent scaling, damage, and crushing; these tools have common characteristics: sharp cutting edge, sizeable front Angle, front tool polishing, high-speed cutting, fine chips.

In the development of the new energy industry, wind energy as a clean, renewable energy, more and more attention from countries worldwide; European countries, the United States, and China have given strong support and promotion in their energy planning. We in China's super hard tool industry can provide high-quality tools and professional processing technology and always focus on providing overall solutions for metal cutting needs. In the long-term cooperation with many fan parts manufacturers, it has accumulated rich experience and strictly meets the processing requirements of wind power parts manufacturers.

The working environment of the wind unit is harsh, and many factors, such as fatigue resistance, reliability, and vibration absorption, have high requirements. The gearbox, wind turbine hub, bearing (slewing support and gear), fan spindle, and wind turbine base are essential working parts for wind turbines. At the same time, they are also difficult to process, have high precision requirements, and have large processing parts. ZYsuperhard engineers offer a range of process solutions to help wind power industry users stand out in the fierce market competition.

The wind power gearbox is one of the essential parts of the wind turbine. Because the installation site of wind turbines is complex, reliability and service life requirements are high, so the gearbox should have enough rigidity, suitable support structure, and wall thickness to meet the complex force needs. Commonly used materials are ductile iron and other high-strength cast iron. The mechanical structure of the gearbox is complex and large, requiring hundreds of hours of precision machining. High precision double table horizontal boring and milling machining center is used in machining parts.

Machining types of wind turbine gearboxes include milling (corn milling cutter and three-sided edge), drilling, and boring.

The wheel hub is also one of the essential parts of the wind turbine; its structure and stress deformation is complex, directly affecting the wind turbine's regular operation and service life. Therefore, it has high strength, good reliability, long fatigue life, and intense vibration absorption to meet the operating conditions of -20℃~40℃. The standard material is cast low-temperature, high-impact ductile iron. The main machining types of wheel hubs are milling and drilling.

The wind turbine hub volume is enormous; the general processing cycle is long. A customer once encountered such a processing problem: although its machine tools ran at total capacity, it could not complete the production task on time. To help customers tide over difficulties, we designed a non-standard indexable forming tool for them, supplemented by related blades, cutting line speed Vc up to 200m/min, each tooth feeds fz0.14mm, cutting depth ap1~2mm, production efficiency is greatly improved, the production cycle of the wheel from the original 30h shortened to within 16h. The customer was able to deliver the goods smoothly and avoid significant losses.

The double eight-edged face milling cutter is very suitable for wheel hub milling. The double eight-edge milling cutter blade adopts a cheerful front Angle design, each blade has 16 cutting edges, and the same milling cutter can meet the application occasions of rough and fine machining with economy and versatility.

Wind power parts processing also includes fan spindle, fan base, connecting flange, fan tower, planetary frame, fan blades, etc. For processing these parts, we can provide complete turning, milling, and hole machining solutions, committed to improving the efficiency and competitiveness of the processing for our customers.

Wind power bearings, due to the harsh environment and high maintenance costs, often use better performance 42CrM0 as the primary processing material, while the use of heat treatment process to improve the service life of wind power bearings, heat treatment hardness reached HRC45 or more, and the size and diameter, processing difficult.

For example, the processing requirements of wind power bearings are:

(1) run-out of end datum < 0.005mm;

(2) bottom run-out < 0.005mm;

(3) Channel surface roughness Ra0.3μm;

(4) The wall thickness difference of the thrust ball-bearing shaft ring is < 0.01mm.

Because of the above requirements, only the grinding process can be completed. Still, with the rapid development of the manufacturing industry, enterprises not only need high-quality products but also put forward high efficiency, low cost, and other requirements, so the hard turning (car instead of grinding) process is the development trend of wind power bearing industry; its processing efficiency is high, low cost, the grinding process can not compete with it.

The complex turning process has higher requirements for cutting tools, which need to have higher hardness, wear resistance, impact toughness, etc. Currently, the tool material that can realize hard turning of wind power bearings is mainly the CBN tool, which is the cutting tool suitable for processing hard materials.

Among them, we can provide cutting tools that can efficiently hard turn wind power bearings, which have excellent wear resistance, and can withstand intermittent cutting, strong impact toughness, and then adopt dry cutting to effectively reduce environmental pollution; For the single-sided composite CBN tool, there is no hole in the middle, and it is also used with the pressure plate type turning tool bar, and the unilateral cutting depth is about 1mm.

ZY-superhard has always adhered to the development concept of "not big but complete, only high precision", cooperated with more and more wind power bearing factories, and gained a good reputation.

Contact: Nina Qiao

Phone: 86-13526572721

E-mail: cutting@zy-superhardtools.com

Whatsapp:86-13526572721

Add: AUX Industry,Zhengzhou City,Henan Province,China

We chat