MCD High Light CNC Inserts

Single crystal diamond tool is also known as single crystal cutting tool, single crystal diamond tool, single crystal diamond blade, etc., is the main cutting tool in the field of ultra-precision machining, the general quality of the cutting tool is greater than 0.1g, the minimum length is not less than 2mm, can be processed with extremely high workpiece accuracy and extremely low surface roughness, the cutting effect is very bright, can achieve mirror processing, It is the ideal tool for ultra-precision machining. According to its material source is different, single crystal diamond tool is divided into MCD and ND two kinds, MCD is a synthetic diamond single crystal, ND is a natural diamond single crystal, due to the small number of natural single crystal diamond, the price is expensive, MCD single crystal tool is widely used.

APKT160402 / APKT10404 / APKT160408 / APKT113502 / APKT113504 / APKT113508 / DCGT11T302 / DCGT11T304 / DCGT11T308 / DCGT070202 / DCGT070204 /DCGT070208 / VCGT160402 / VCGT 160404 / VCGT160408 / VCGT110302 / VCGT110304 /VCGT110308 / CCGT060202 /CCGT060204 / CCGT060208 / CCGT09T302 / CCGT09T304 / CCGT 120402 / CCGT 120404 / CCGT120408 / TMNG160408 / TNMG160404 / WNMG080402 / WNMG080408 / SEHT1204 / TCGT090202 / TCGT110202 / TCGT 16T302 / TCGT16T304 ......

Widely used in Watch industry, digital industry, automotive industry, CNC machine tools, computer engraving machine, aerospace industry and others.

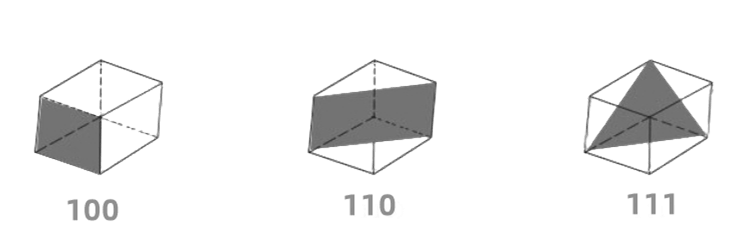

Single crystal face selection

The diamond crystal has three main crystal faces (100), (110) and (111), of which the (100) crystal face is the most difficult to wear, so we choose the (100) crystal face as the front and back knife face of the diamond.Generally, the crystal face of a single crystal diamond tool should be selected according to the requirements of the tool. In general, if the diamond tool is required to obtain the highest strength, the (100) crystal face should be selected as the front and back face of the tool; If the diamond tool is required to resist mechanical wear, the (110) crystal face is selected as the front and back face of the tool; If the diamond tool is required to resist chemical wear, it is appropriate to use the (110) crystal face as the front knife face of the tool, the (100) crystal face as the back knife face, or the front and back knife face are all using the (100) crystal face, and these requirements need to be achieved with the help of crystal orientation technology.

Contact: Nina Qiao

Phone: 86-13526572721

E-mail: cutting@zy-superhardtools.com

Whatsapp:86-13526572721

Add: AUX Industry,Zhengzhou City,Henan Province,China

We chat